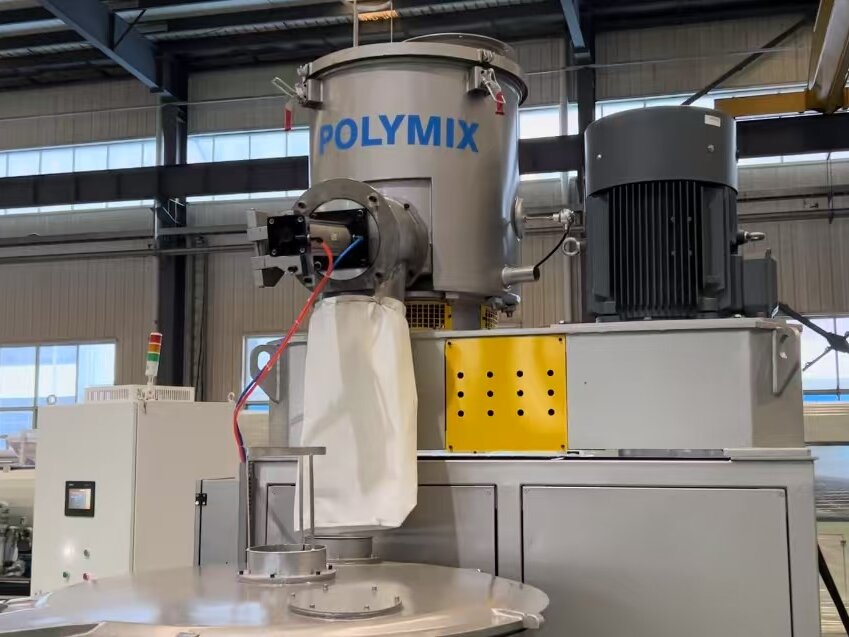

High speed mixer

| Electrical Parts | Schneider Brand |

| Motor | Simens motor |

| Temperature Controller | Omron brand |

| Inverter | ABB brand |

| Gearbox | Jiangying Gearbox |

| Your requirements | We make machine as per ur demands |

Your Premier Mixling Machine in China

High-low mixing cold and hot mixers, and high-speed mixers are mainly used for: mixing and coloring of polyvinyl chloride resins, coloring and drying of polyethylene and polypropylene particles, drying of hygroscopic resins such as ABS polycarbonate before molding, mixing of phenolic resins and other processes. It is one of the most popular equipment in plastic processing plants, and it also has many uses in rubber, pharmaceutical, dyeing, and other industries. Because it has the advantages of fast mixing, uniform mixture, good absorption of resin to enhancers, convenient machine operation, easy cleaning, sturdy and durable, and compact structure. It has gradually replaced low-speed mixers and is widely used in producing various plastic industries.

- The mixer and the electric control box are installed on the cement foundation respectively and fixed with anchor bolts.

- The mixer is heated by a resistance heating ring, and the high-ignition-point mechanical oil in the heating jacket is evenly transferred to the pot body, and the power cord is connected through the underground wire protection pipe.

- The mixer is cooled by water, passing the cooling water through the outer jacket and the cooling ring to achieve uniformity.

Product advantages

This mixer is equipped with advanced Siemens series PLC technology, which can realize a complete set of automated mixing processes, including automatic feeding, automatic mixing,

automatic temperature measurement, automatic discharge, and automatic alarm system, which can successfully liberate a large number of productivity, thereby greatly reducing production costs but at the same time increasing production efficiency

Instructions for use

- Connect the power supply and gas source under the guidance of the manufacturer

- Use a feeder or other feeding system to transport the powder to the hot mix above

- Heat and mix at high speed according to the formula

- The finished hot mix material is automatically discharged and directly enters the cold mix

- Cool the material quickly through circulating water cooling in the interlayer

- The cold mixed material meets the various properties of the hot mixed finished product and is less affected by moisture at room temperature

- Data Sheet

- Videos

- Send Enquiry

Model SRL-Z100/200 SRL-Z200/500 SRL-Z300/600 SRL-Z500/1000 SRL-Z800/1600 Total volume(L) 100/200 200/500 300/600 500/1000 800/1600 Effective volume(L) 65/130 165/350 225/360 350/650 625/1250 Stirring paddle speed(RPM) 650/1300/200 475/950/130 475/950/100 430/860/50 370/740/50 Mixing time(S) 8~12 8~12 8~12 8~15 8~15 Motor power(KW) 14/22/7.5 30/42/11 40/55/11 55/75/15 83/110/22 Dimensions(MM) 1950*1600*1800 4580*2240*2470 4800*2640*2480 5600*3000*3100 5170*3200*4480 Weight(KG) 2200 3400 3600 6500 9800