PVC Marble Sheet Machine

| Extruder | SJZ80 conical twin screw extruder |

| Mold | T-die from JC time brand |

| Forming machine | Three-roller |

| Surface hot transfer | Two rollers up three roller |

| Cooling bracket | Aluminum pipe with side cutting knife |

| UV protect film | up haul-off |

| Haul-off | two rollers |

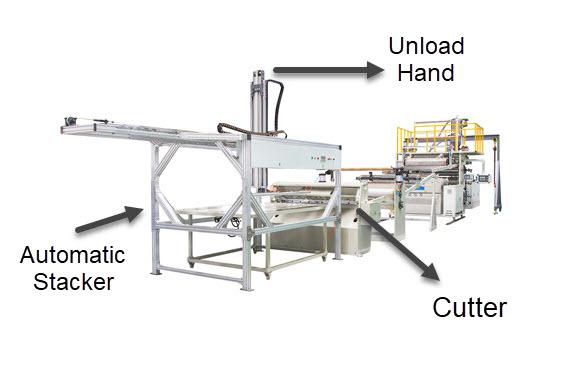

| Cutter and stacker | No-noise cutter and automatic arm |

| Control system | Siemens touch screw and Siemens PLC |

| Electric parts and motor | Siemens Ac motor, Schneider and Ormon electric |

Your first choose for SPC vinyl floor making machine manufacturer in China

BENK PVC marble sheet machine also named PVC sheet making machine which is used to produce PVC sheet with thickness of 1-3mm, PVC sheet can be used as indoor flooring panel, furniture surface, wall panel, the price of PVC sheet is very cheap, as it is very thin whose has lighter weight comparing with PVC foam board. So how to make PVC foam board, it has same extrusion process with PVC marble sheet, but their downstream machine is totally different which start from Die.

BENK is a professional PVC sheet making machine and PVC foam board machine manufacturer in China, their raw material is PVC, and main extruder are conical twin screw extruder (SJSZ80/156 conical twin screw extruder), BENK has supplied many plastic sheet machine to plastic marble sheet manufacturer in India and China since two years ago, now we have rich experiences in plastic extrusion process technical.

BENK sheet extrusion line use three-roller or four-rollers with die to forming sheet, BENK PVC board use die with vacuum table to forming board, usually our client will carpet PE film with different painting in the surface of sheet, and will use UV film as the protector in the end.

The different between with sheet and board is their thickness, PVC sheet is around 0.3-1.5mm, PVC board will be 2-18mm. If you want to know more our plastic extrusion step and die design as well as our prices of plastic sheet and board extrusion line, please contact me for more details.

- Production images

- Data Sheet

- Testing Video

- Send Enquiry

Data of SPC vinyl floor making machine:

| Extruder | SJZ80/156 |

| Output | 350-400KG |

| Finished sheet wide | 1220mm |

| Finished sheet thickness | 1-8mm |

| Main motor | 75KW |

| Control | PLC |

PVC Marble Sheet Machine: The Ultimate Importers Guide in 2018

There is a new revolution in the decorative industry.

And that revolution is PVC marble sheets.

They are beautiful, environment friendly, cost-effective and more!

For this guide, I’ll teach you all there is to know about the PVC artificial marble sheet production line.

You’ll get all the knowledge you need to set up and buy a PVC Marble Sheet Making Line in China.

Great! Let’s start with the basics.

Chapter 1: What are PVC marble sheets

1.1 Definition of PVC marble sheets

Figure 1: PVC marble wall panels

A PVC marble sheet is a thin rectangular plastic sheet that mimics natural marble designs.

Most PVC marble sheet manufacturers are making marbles sheets with a thickness of 3.5mm, 1220mm width and 2440mm length.

Okay, this seems to be the current standard.

But, I have good news for you; with our plastic marble board line you get to manufacture sheets with a diameter of 1 to 8 mm.

More about this later in this guide:

1.2 Other names for PVC Marble Sheets

PVC marble sheets is the most popular term:

- PVC for polyvinyl chloride—the world’s third most used synthetic plastic polymer.

- Marble—because they look like actual marble sheets

- Sheets—for their thinness

But you also encounter other names including:

ü PVC Marble Panel

We also call them PVC marble panels because you can cut them into small sized widths to decorate your walls.

So, when their width is similar to marble panels, we call them PVC marble panels.

ü PVC Wall Panel

PVC wall panel has the same explanation as PVC marble panel.

ü PVC Faux Marble Panel

Faux means not real. So because PVC marble panels are not real marble, on that we stick the marble design film on the sheet, thus we call them PVC faux marble panels.

Figure 2: Real Marble Wall Panels

- PVC artificial marble decorative sheet/ PVC Imitation Marble Sheet

Intimation, faux, artificial have similar meanings.

ü UV Marble Panel

Some manufacturer use UV processing on the surface of PVC marble. This make marble sheet more wear-resistance. It is a new technology currently used in PVC marble sheet manufacturing.

However, you will need to buy the the UV coating machine separately.

ü Decorative marble panel

Decorative marble panel is because sheet will be used in wall decoration

ü Marble Ceiling Panel

Some end-user will use the sheet as ceiling panel, then we call it marble ceiling panel.

Figure 3: PVC marble sheet used as ceiling

Figure 3: PVC marble sheet used as ceiling

1.3 Why should you manufacture PVC Marble Wall Panels

Ø Growing demand:

First, the demand for PVC products, as shown by several studies, is set to increase. A study by Plastics Today shows that it could increase 3.2% annually through 2021.

This growth will be felt in North America, Western Europe, and Asia-Pacific countries, which have the largest PVC market share.

And China being the world’s largest PVC marble sheet producer.

Ø It’s a better alternative to conventional construction materials

PVC marble sheets solve all the limitations of wood and marble. Plus they bring many advantages to the table.

Let’s talk about them next:

1.4 The difference between PVC artificial marble sheet and natural marble wall covering

| PVC Sheets | Natural marble | |

| Price | About $5 to $16 per piece (2.98 m²) | About $100+ per square meter |

| Material | PVC resin, CaCo3, plastic additives | Mined from a marble yard |

| Rigidity | Highly rigid with good impact strength | Has a hard surface but it’s brittle and prone to cracking |

| Weight | Light weight | Heavy might require lots of labor to lift |

| Maintenance | Minimum | It’s a porous rock that requires high maintenance since it can become discolored. |

| Characteristic | Can be recycled

No-toxin to people |

Very difficult to recycle

Produce radiation to people |

These are some differences between natural marble wall covering and plastic stone boards.

You should also know that marble has a high installation cost.

Conclusion

In this article, you have to gain some basic knowledge on PVC marble sheets.

In the next chapter, let’s look at the PVC Marble Sheet production Equipment in depth.

Chapter 2: PVC Marble Sheet Production Line Equipment

2.1 Introduction to PVC Marble Sheet Production Plant

A PVC Marble Sheet Plant is a building or group of buildings where you will manufacture marble wall sheets using a collection of machines.

So, which machines will you need?

Take a few minutes to watch this video:

You have seen some machines.

We can group them into three groups based on their functions:

| a) Raw Materials Mixing and Loading Machines | |

| Machine | Quantity |

| 1. Screw Loader | 1 |

| 2. PVC Mixer/High speed Mixer/Hot and Cold Mixer | 1 |

| b) PVC Marble Sheet Extruding Line | |

| 1. Screw loader | 1 |

| 2. SJSZ80/156 Conical twin screw extruder | 1 |

| 3. T-die from JC time brand | 1 |

| 4. Three-roller Calender with marble decorative film laminating roller | 1 |

| 5. Temperature controller for calender rollers | 1 |

| 6. Cooling bridge with longitudinal side cutting devices | 1 |

| 7. Haul off system with two rollers | 1 |

| 8. Transverse Cutter | 1 |

| 9. Stacker | 1 |

| c) Auxiliary machines for recycling Plastic | |

| 1. Plastic Crusher/Grinder | 1 |

| 2. Plastic Pulverizer/Miller | 1 |

2.2 Working process of PVC Imitation marble sheet production line:

Before we talk about the working process of the PVC marble machine, the first thing you require in your plant are raw materials.

The raw materials for PVC laminated marble stone sheet are:

| Raw material | Function |

| PVC resin | It’s the main raw material. For plastic marble sheets, you will use PVC resin SG5. |

| CaCo3 | Calcium carbonate is a mineral filler used to improve the marble sheet’s surface finish, impact resistance, and glossiness. It is availed in powder form. |

| Ca/Zn Compound | It is a heat stabilizer that prevents PVC from disintegrating during melting, improves the color stability and durability of the final PVC marble sheets. |

| Stearic acid | It’s derived from palm oil and used as a lubricant. |

| PVC Impact Modifier 135A CPE | It increases the impact the resistance of PVC or its weatherability. |

| Recycled PVC marble sheet | Can be mixed with new material to make PVC imitation sheet again |

To make it easy to understand how the machines work together in a plastic marble sheet plant, I prepared a flow process for you:

Figure 4: Plastic Marble Sheet Flow Process

The final marbles sheets can be loaded into a conveyor. Then UV treated before they are packed and shipped off to the customer.

2.3 What is the correct operation method for the PVC Marble Sheet Production Line?

Next, let’s talk about the operation method for the Plastic Imitation Marble Machine:

We will cover the start up procedure and how the machines function in full production.

1) Preheating

Before preheating the extruder, you will first ensure that all the instruments such as the temperature controllers are connected to the control panel and functioning.

Figure 5: PLC control panel

Figure 5: PLC control panel

You or your staff will also check to see if there is cold water flowing through the barrel of the extruder.

Next, you will turn on the heating system to warm up the machine to about 50oC.

Once you reach this temperature, you can start heating up the extruder to production temperatures.

Figure 6: Extruder Barrel with fans and pressure gauge

Figure 6: Extruder Barrel with fans and pressure gauge

We have equipped our machines with PID temperature controllers. They help the extruder reach the melt temperature precisely.

Remember that it is easy to heat up the extruder than cool it.

2) Extrusion

For extrusion to begin, you must feed dry PVC resin and other additives into the feed hopper.

All the materials have to be in powder form.

But, how do you dry and mix them?

Well using the hot speed mixer that has a hot tank and cool tank. Both tanks have blades to mix materials together.

Figure 7: Mixer Machine (hot tank top; cooling tank bottom)

After they are mixed and cooled, you will use the spring loader to feed them into the hopper.

Figure 8: Screw loader

Figure 8: Screw loader

Next, we will look at the Plastic extrusion process steps:

But first I want you to take a look at this diagram of an extruder:

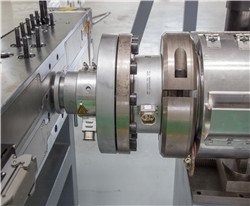

Figure 9: Extruder diagram showing temperature zones of molten plastic

Figure 9: Extruder diagram showing temperature zones of molten plastic

- Screw motor

- Raw materials inside the hopper

- Breaker Plate

- Extrudate

In the hopper, the raw materials descend onto the rotating screws in the barrel by the action of gravity.

These screws convey the raw materials forward. And the barrel is divided into temperature zones with temperatures increasing as you move down the barrel.

Temperature zones include:

- Feed temperature zone

- Transition temperature zone

- Melt temperature zone

You might wonder why different zones exist?

Well, we want the PVC resin and additives to melt gradually as they are pushed down the barrel by the screws.

This configuration also prevents degradation of the polymer matrix. And allows plastization to take place.

You should also know that there is intense pressure and friction inside the barrel.

It generated by the motion of the screws.

The screws are prone to wear and tear, and have to be replaced time to time.

This extra heat from the motion of screws may be so high that you can shut off the heating system and maintain the melt temperatures through friction.

And if too much heat is generated, the extruder has fans that air-cool the barrel.

If they are not effective, you can pump cooling water into jackets on the extruder.

After the plastic polymer is melt and plasticized. It’s time for it to leave.

It ejected from the extruder’s front at high pressure.

This is called extrusion and the molten polymer is called an extrudate.

Next, let’s see how this extrudate forms flat & smooth plastic sheets.

- Molding

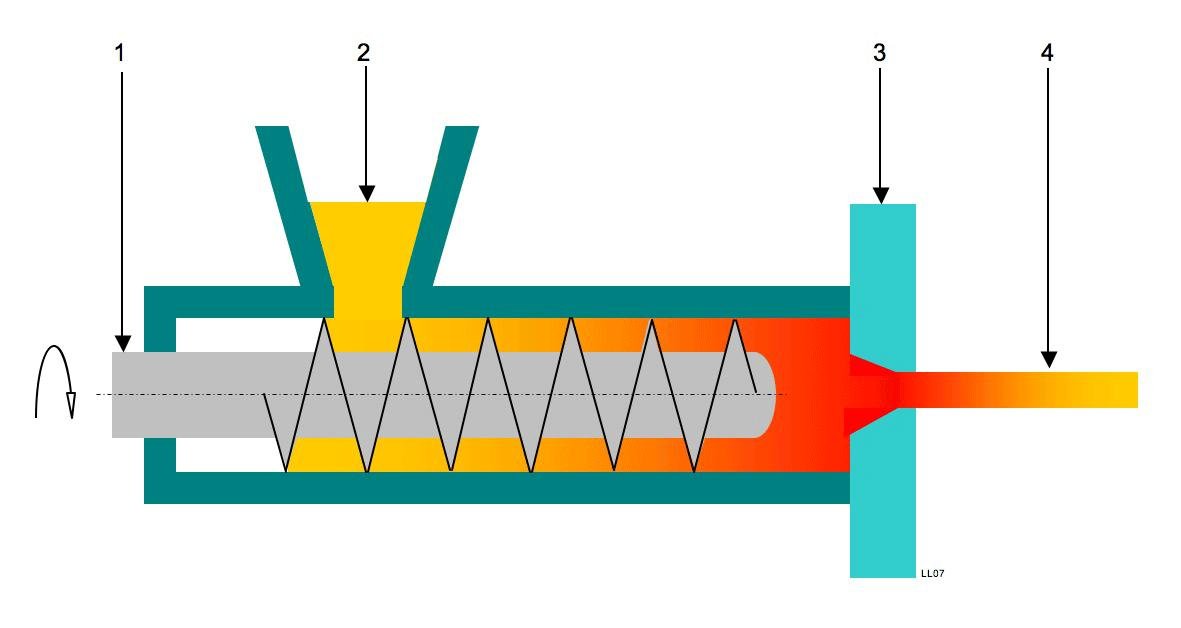

Figure 10: Plastic flow to the die

Figure 10: Plastic flow to the die

Moulding is the process of giving the plastic sheet its shape.

When the molten plastic leaves through the front of the extruder’s barrel, it passes through a breaker plate/screen before entering the die or mould.

We use a breaker plate (which is a metal screen with numerous small holes) to generate back pressure in the barrel and remove contaminants that can damage the calendering rolls.

The t-shaping die will give the molten plastic its shape (flat and rectangular).

You can also set the sheet’s thickness at the die. Our die allows you to adjust its gap.

- Forming by three-roller calendar

Figure 11: Three-roller calender

Figure 11: Three-roller calender

You will notice something unique in the PVC artificial marble sheet making machine: A set of three press rollers.

They are called calendering rollers. Together, they smooth out the sheet, give it a uniform thickness and apply patterns to the plastic marble sheet.

Each rollers is heated and temperature controlled.

We need to keep the extruded plastic hot so we can easily form it.

So how do the rollers work?

The first two rollers form the plastic sheet into the desired thickness and width by applying heat and pressure.

This make the surface of the sheet smooth.

On our plastic faux marble machine, you can lift the two-rollers.

They also have torque motors, which will allow you to control their speed and tension.

The third roller or the embossing roller can have different patterns engraved on its surface.

This allows you to added special effects to the plastic marble sheet’s flat surface.

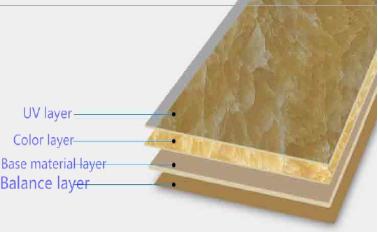

- Hot stamping film on the sheet with a laminating roller

Before the sheet leaves the calender system, it’s hot stamped with a decoration PVC marble sheet film.

The laminating film is about 1.5 to 2mm thick and can adopt many marble effects.

You will have to find a supplier of the marble sheet decoration film.

Some PVC marble laminating sheets on the market are already UV coated.

6) Cooling

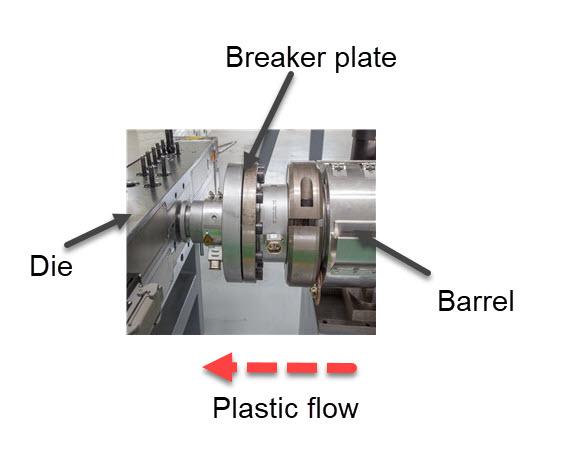

Figure 12: Cooling bracket for cooling PVC artificial marble decorative sheet

Figure 12: Cooling bracket for cooling PVC artificial marble decorative sheet

After the calendering process for the PVC Marble imitated marble sheet, the sheet has to be cooled since it’s still hot.

You will pass the sheet over the cooling bracket.

It’s made of highly polished aluminium pipes that allows the sheet to slide over it.

A side cutting device installed on the line trims the edges of the PVC marble sheet so you can get the desired length, which by market standards is 1220mm.

7 ) Timing for two sides of marble sheet

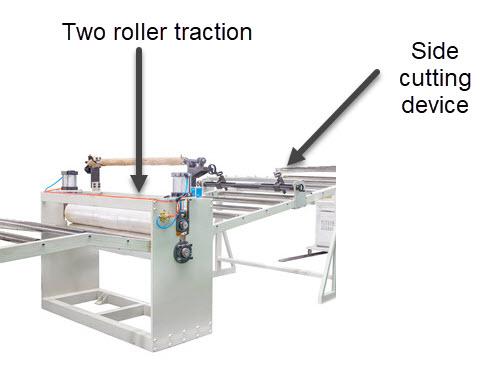

Figure 13: Traction and side cutting device

Figure 13: Traction and side cutting device

As the sheet rolls down the cooling bracket, it guided by two traction rollers.

We use two rollers and automatic control to ensure precise timing and positing of the marble sheet for cutting.

- Transverse Cutting

The PVC Marble Machinery comes with has a transverse cutter, that cuts the plastic marble sheet into the required lengths.

Our cutter machine in particular, has automatic meters and photoelectric sensors for precise cutting.

Once it has the required length, it activates the blade, which is no-noise.

The accurate length is 2400mm.

- Stacking

Figure 14: Stacker with cutter

Figure 14: Stacker with cutter

Stacking is done by the automatic stacker. It has an upload hand, which lifts individual sheets and stacks them on a pile.

You can choose to store or transport the sheets. Additionally, you may perform further processes such as applying a UV layer.

However, this can be avoided by purchasing films with UV layer.

Advantages of our plastic marble sheet making machine

- We use conical twin screws with special design in the extruder, which ensure uniform melting and high discharge of materials. They have high plasticization capacity and can handle formula with more Calcium content.

Figure 15: Conical twin extruders for barrel

Figure 15: Conical twin extruders for barrel

- Our plastic imitation marble machine’s high performance conical double screw extruder adopts electrical parts from famous brands; for instance the main motor is from Siemens, Ormon temperature controllers, and ABB frequency inverter that controls the extruder speed and haul off speed.

- The rollers have an independent oil temperature controller system that allows you to get uniform thickness of the final marble sheet.

- Our three roller calender press adopts vertical, horizontal or 45o These modes gives you more control over the thickness and quality of the sheet.

- The PVC artificial marble decorative sheet production line adopts advanced computer control with a Siemens touch screw and Siemens PLC. This system makes it easy for customers to run the machine.

Figure 16: Coat Hanger T Die

Figure 16: Coat Hanger T Die

- The coat hanger t die is chrome-plated and equipped with fine adjustment screws, which will allow you to adjust the mouth clearance of the die to get the right thickness. The gap setting is from 0.5mm to 8mm.

- The barrel of the PVC sheet manufacturing machine adopts a precision temperature control system, with cast aluminum rings and fan cooling.

Conclusion

In this chapter, we have covered the parts of the Artificial marble sheet production line and the working process.

Next, let’s look at why PVC marble sheets are gaining wide usage in the modern world.

Chapter 3: Characteristics, Advantages and Uses of PVC Marble Sheet Production Line Products

Characteristics

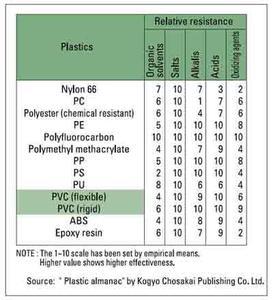

– Extremely high chemical resistance

This mean that PVC marble imitation sheets can maintain their original properties even when there are exposed to chemical reagents like acids or alkalies.

Figure 17: PVC properties table

Figure 17: PVC properties table

– High flame retardant

This means, PVC marble sheets slow the spreading of fire or prevent fire from igniting in the first place.

You don’t need to add flame retardants to get this property. In fact, PVC has a ignition temperature of 455°C.

Thus, when used in a house, it can stop fires or provide time to escape.

– Very good mechanical properties even at higher temperatures

PVC is a stable material. This means its molecular structure or mechanical strength doesn’t change easily even at high temperatures.

Other mechanical properties PVC marbles sheets have include high surface hardness, corrosion resistance, and good flexibly.

– Extremely scratch-resistance

Figure 18: Layers of PVC marble sheet

PVC artificial marble decorative sheet that’s coated with a high gloss UV layer provides a degree of resistance against abrasions and scratches.

– Low production costs

Plastic marble sheets are low cost to produce owing to their cheap and readily available raw materials.

You can also take advantage of economies of scale since you will produce PVC marble sheets in bulk. This allows you to price your products competitively at low prices.

– Low water adsorption < 0.5%

– Low heat conductivity

PVC has low heat conductivity, which simply means that it is not a good at transferring heat.

Therefore, PVC marble sheets that cover walls may slightly help in heat retention.

Advantages of PVC Marble imitated marble sheet

1) Wide selection of colors and designs

Figure 19: PVC marble sheet designs

Figure 19: PVC marble sheet designs

Once you have made the base of the PVC marble sheet, you can apply many colors and styles to it.

Your products will be used to replace plywood, MDF or marble walls panels.

And they will look good for a long time.

2) Offers green environmental protection

We consider the UV marble sheet green products because they contribute to environmental protection.

For instance by replacing wood products, they prevent the destruction of trees.

You can also recycle them using plastic recycling equipment such as the plastic crusher + plastic miller.

3) Non-toxic & harmless

We say it harmless because PVC marbles don’t contain formaldehyde found in many wood products such as MDF boards.

Nor do they contain dangerous metals such as lead.

4) Moisture-proof and don’t wrap

Wood products absorb water and may wrap & rot.

On the other hand, PVC marble faux sheets are impervious to water vapor.

This quality makes them applicable in high-moisture areas such as bathrooms or kitchens.

5) Offers safety

Because they are flame retardant, corrosion resistant, acid and alkali resistant, PVC marble imitation sheets are safe to use at home and in commercial areas such as schools and hospitals.

6) Convenient installation

Since artificial marble sheets are light, they are east to install. And thanks to their good mechanical features, they require minimal maintenance.

7) Long service life 20 years+

PVC marble wall sheets have a long service life of about 20-30 years.

8) Excellent fabrication properties

You will provide your customers with 8ft x 4 ft PVC faux marble sheets. Some customers will then cut them to any size they want.

What’s more, will find it to easy to saw, drill, screw, bond, nail, and glue plastic marble sheets.

Uses of PVC Imitation Artificial Marble Board

Clients all over the world are choosing PVC Imitation Marble Sheet for their eye-catching designs, wear-resistance and durability.

Here are places where they are used:

- Decoration in airports, hotels, shopping malls, subways, hospitals, laboratories, kitchens, home walls…

- Trade fairs exhibition stands

- Exterior and interior signs

- Wall partitions for offices

- Cladding

- False ceilings

- Bank cash counters

Chapter 4: How to find the best price for PVC marble sheet making machine

Ready to buy a PVC marble sheet production line?

Getting the best price is important.

And in this chapter, I will tell things to consider in order to get the cheapest price from PVC sheet machine manufacturers in China:

What to consider to get the best PVC marble sheet machine price

1) Capacity

First, you should look at the maximum capacity of the machine.

This value is expressed in kilograms per hour.

For example, our PVC Imitation Marble Sheet Production line has a maximum capacity of 600kg/H.

2) Quality of parts used in machine

Some PVC marble sheet production plant manufactures may not use high-quality electrical and mechanical parts from respected manufacturers.

In this case, they might price their machines lower.

However, at Benk we use electrical parts from proven manufacturers with a world-wide reputation.

For instance, this ABB variable frequency inverter from ABB:

Figure 20: ABB High-quality Frequency inverter

3) Automation

In terms of automation, there are two types of PVC marble decoration sheet production line machines: Automatic and Semi-automatic.

A fully automatic machine will requires less labour to run it.

For instance, our machine is fully-automatic from loading of the raw materials into the extruder to stacking of the final products.

4) Computerized vs non-computerized

The computer system performs tasks that are repetitive and continuous. In turn, removing the need to hire manual labour.

While computerized systems may be more expensive, they have many advantages.

For instance, our computerized plastic stone board manufacturing machine promote plant productivity, more efficiency, high product quality, better worker safety, reduced problems/down time and uniformity of products.

Certification

5) Certification

Figure 21: Ce certification logo

Figure 21: Ce certification logo

Your first question to a PVC marble sheet line supplier is to ask if the company’s products have passed various regulations, tests and standards.

Failure do this may even lead to sub-standard goods been seized at the border since they can’t get accepted in some countries around the world.

We comply with the highest quality standards and our machines have passed various certifications including CE, ISO9001:2008, UL, QS, GMP.

They will be accepted anywhere in the world including countries in Europe.

So what is PVC marble sheet price in China?

The plastic sheet making machine price in China varies according to the manufacturer.

But generally, it’s between US $65,000-200,000.

Other things that may influence price includes the client’s requirements, after-sale services and the auxiliary machinery required.

Chapter 5: Get the best China PVC Marble Machinery from Benk

Figure 22: Business partner

Figure 22: Business partner

Now that you know how to find the best price for the marble sheet making machine.

We want to tell you why you should choose us as your equipment provider.

We have been producing plastic making machines for the last 10 years.

Through close collaboration with our customers we continuously improve and update technologies used in our PVC sheet production machines.

Here are more reasons for you to consider us:

Ø Technical support from a well-qualified team

We have well-qualified engineers with many years in the design, testing, debugging and installation of the PVC Marble Machinery.

They will provide technical assistance to you as you choose the equipment such as matching the right screw combination to the formula.

After you sign the contract with us, we will provide water and electricity drawing to help you prepare for the arrival of the machine to your factory.

Ø PVC marble sheet installation service

Figure 23 Installation service

Figure 23 Installation service

We can send one of our engineers to help install the machine when it arrives at your factory.

You will only pay their air fare, accommodation, daily commute, and salary, which is 50USD per day.

The engineer will help install the machine. He will also come up with a formula for you so you can start producing your beautiful marble sheets immediately.

With time you will have to adapt your formula to fit the raw materials available in your area.

Ø Training services

Our engineer can also train your staff on how to operate the PVC artificial marble decorative sheet production line until they can operate on their own.

We also provide support services in the future in case you encounter any problems.

We have three engineers helping our clients overseas at any given time.

They can provide support online.

If they can’t solve the problem through the internet, we will arrange tickets for them to travel to your plant.

Ø Project Analysis Report

We can provide a project analysis report for the PVC marble sheet production plant.

It will elaborate further about the equipment and machinery requirements for setting up a PVC imitation marble sheet production line.

This project report will help you understand the costs, expenditures, overheads and utilities.

We can also help you calculate the built area you need to house the PVC marble sheet machine.

In case you need more information on this contact the manager at Benk.

Ø Custom Solutions

We design and make each project as per the customer’s needs.

For instance, we can customize the machine based on the output volume you require.

In the past, we have customized the electrical connections based on the customer’s country of origin.

Ø Warranty

We not only use high quality parts in our machines, we also provide a long warranty of 13 months for electrical parts.

You also get a 6 month supply of damaged parts.

If you need a replacement submit a request to us, and within 7 working days we will send the parts.

Frequently Asked Questions

1. How long does it take to deliver the machine?

It takes 30 working days to deliver a standard machine.

However, if you order a customized PVC sheet making machine it may take up to 45 days to prepare.

If we have the parts in our warehouse, we may even deliver the machine within a shorter time frame.

2. Why do I choose your company?

We consider customers as part of our family and we treat each order with the topmost professionalism and care.

We also maintain strict ethics.

After you purchase the machine from us, we will continue cooperating with you to make sure our products satisfy your needs.

In addition, we have all the certificates to prove that our machines are of very high quality. And in the years we have been in business, we have never received a legal claim from an unhappy customers.

- What should I prepare to install the PVC marble sheet production line?

You will need the raw materials e.g PVC rein, CaCo3, and other additives.You can order them from overseas manufactures in China.

We will also supply diagrams so you can prepare the waterline and electrical line. You can also request a workshop layout for us.

4. Where is your factory located? Can I visit?

All our customers are welcome to visit our warehouse.

You can find use in Zhangjiagang, Suzhou, Jiangsu China. Before booking a visit, contact the manager and tell us your flight number and time. We can even arrange to pick you up from the Airport.

5. What happens if machine arrives in my factory and doesn’t work?

First this is highly unlikely because we will assemble and test your machine before we pack it in wood pallets covered by plastic film for safe shipping by sea.

You can even come watch the machine working properly in our workshop.

But in case of problems, we will send our technician to your factory to help with repairs. And if any part was substandard, our warranty will cover the replacement.

6. How can I trust your company and Artificial marble sheet production line

We have sold many plastic machines all over the world to countries such as Russia, Turkey, and India. Our excellent service, fair price of our PVC sheet making machine continues to draw customers. We always open to questions order or no order.

Conclusion

We here to help you manufacture PVC marble sheets.

We also have related machines that manufacture plastic sheets: The PVC foam board machine, SPC flooring machine, and Plastic Tile Extrusion machine.

For more information send an inquiry to Mr Tony. We will be happy to help you.

References: