Plastic Extrusion Mould

Other production

Why Big Brand Trust BENK MACHINE

What is the benefits and service you can get from us when we cooperate

Helpful Resource To Support Your Business

Ultimate Guide to Plastic Extrusion Moulds

This article will introduce you plastic extrusion moulds or “plastic extrusion dies, which in conjugation with the extruder produce different extrusion products.

Types of plastic extrusion moulds include;

- Sheet dies for films

- Profile dies for door and window profiles

- Annular dies for pipes and tubes such as PP-R, PVC, HDPE pipes

- Co-extrusion dies for multi-layer, multi-wall plastic extrusion products e.g. Double wall corrugated pipes.

Figure1: Plastic Extrusion Mould for Hollow Sheet

Figure1: Plastic Extrusion Mould for Hollow Sheet

Plastic extrusion die design is an important but challenging task. It requires a detailed knowledge of the properties of the molten polymer including its flow characteristics, melt temperatures, heat transfer characteristics, melt viscosity and more!

You also need extensive experience with the extrusion process. With over 10 years of extrusion experience, Benk is the place to order your custom plastic extrusion mould.

We’ll look at plastic extrusion moulds in depth to make your buying process easier and save you money.

Chapter 1: What is Extrusion Moulding?

Figure 2: PP Hollow Sheet Mould during production

Figure 2: PP Hollow Sheet Mould during production

1.1 Definition & Plastic extrusion moulding products

Extrusion is the process of heating and shearing thermoplastic material (e.g. PVC powder) inside a heated barrel with a rotating screw.

After plastic powder forms a molten polymer, the melt is pressurized and ejected into a mould or die—which is passage or cavity that has the shape of the product being manufactured.

For instance, sheet dies have a flat and slit-like shape. For pipes, the cavity is annular or ring-shaped.

After the molten leaves the die, it’s called the “extrudate,” and it’s drawn into downstream equipment by the application of slight pulling pressure. Calibration, cooling, and cutting of the products will take down the line.

Production of PVC pipes example:

1.2 Desired outcomes of plastic extrusion molding process

So what are the objectives of the plastic extrusion molding process? Well, they include:

- Impacting the correct surface finish (aesthetics) on the extruded product

- Impact the right shape and size with little deviation to the set standards.

- Ensure that the molecular interaction within the plastic melt results in the desired physical properties.

- Minimize the pressure drop as the material moves through the die.

1.3 Plastic Extrusion Mould Design

The performance of the die is influenced by a number of factors including:

- Ratio of the barrel’s cross-section ratio to the mould’s cross-section.

- The dimensions of the die – such as its length.

- The type of material used to make the die. For instance, if there is a lot of friction between the inner walls of the die with the molten plastic, it might lead to cosmetic defects on the product’s surface.

- The flow rate in the die. It’s essential to have a uniform and streamlined flow.

If there is any stagnation of the molten polymer inside the die, it might cause polymer degradation since the melt is exposure to hot spots for an extended time.

1.4 Main parts of the extrusion die

In this section, we’ll look at the sheet die to better learn how plastic moulds work. The plastic mould can be divided into four key sections:

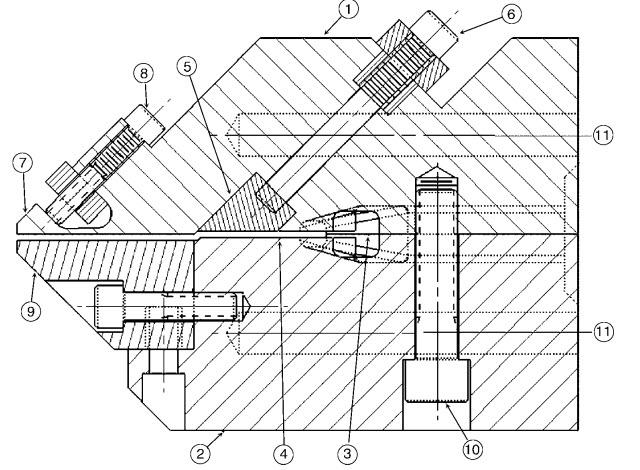

Figure 3: Coat Hanger-Type Sheet Die Credits M. M. Kostic and L. G. Reifschneider, “Design of Extrusion Dies”

- The main inlet port (2) Manifold or Distribution (3) Island or Land section (4) Die lip

- Adapter: It joints the mould to the extruder’s barrel. A breaker plate and screen pack are installed just before the die to regulates the back pressure in the extruder and screen out contaminants.

- Distribution or Manifold Section: It distributes the melt evenly across the die’s orifice.

- Land section

The land section maintains the shape until the extrudate exits the mould.

- Exit/Die lips

The extrudate leaves the die through the die lips.

Detailed diagram of a coat-hanger sheet die

Figure 4: Detailed cross-sectional diagram of coat hanger-sheet die Adapted from M. M. Kostic and L. G. Reifschneider, “Design of Extrusion Dies”

Don’t worry if coat hanger sheet die looks complicated, it’s very easy to understand.

- Upper die plate

It’s the top part of the coat-hanger die. If you look at the diagram, you’ll notice the presence of a cartridge heater running through its length (11), choker (5) & choker adjustment bar (6), and the flex die lip (7) and its adjustment bolt ( 8).

- Lower die plate

The lower die plate also has a cartridge heater. It can be moved up and down with the die bolt (10) to vary the gap of the island or land (4).

- Manifold

The manifold has to evenly distribute the melt in the land section. Sheet dies are named after the shape of the manifold.

There are T-dies, coat-hanger dies, and fishtail sheet dies. It’s very essential for the melt to fill into the land section evenly.

- Island

It maintains the flat shape needed for sheets.

- Choker bar

The choker bar controls the flow rate of the polymer melt into the die lips. It’s also called the flow resistor bar.

Controlling plastic flow in die video:

- Choker bar adjustment bolt

You will use the choker bar adjustment bolt to lower or raise the choker bar.

- Flex die lip

The flex die lip also adjustable and allows you to further fine tune the flow of the melt as it leaves the die.

- Flex lip adjustment bolt

It’s used to control the upper flex die lip.

- Lower lip

The lower lip works in conjugation with the upper lip to set the thickness of the sheet.

- Die bolt

It holds the lower and upper die plates. During maintenance, you can open the die bolt and split the die into two parts.

- Heater cartridge

Should provide uniform heating inside the die.

1.4 Plastic extrusion die heaters

Figure 5: Heaters for plastic mould

Figure 5: Heaters for plastic mould

In addition to cast heaters, there are several types of heaters used in plastic extrusion molds.

In figure 5, you can see the power supply cables from the extruder’s electrical cabinet supplying electricity to the cartridge heaters.

You might be asking why do we need heaters in the die?

Die heaters don’t increase the temperature of the polymer, they only maintain it. The molten polymer has already been heated in the extruder.

So plastic extrusion mould’s temperature is the same as the melt’s temperature. Some dies have multiple temperature zones like the extruder barrel. Each zone will have a thermocouple and temperature controller.

In case heaters fail in one zone, other heaters can maintain the required temperature.

To produce a glossy finish on the surface of the plastic products, it’s a common technique for the die to have a higher temperature than the molten polymer.

Types of plastic mould heaters

- Cartridge/coil/pencil heaters

Figure 6: Cartridge heaters

Figure 6: Cartridge heaters

They are tubular in design. Inside, they have a nickel-chrome wire that’s wound around a ceramic core. Heat is dissipated by the resistance of the nichrome wire to the flow of AC current.

- Plate heaters

Unlike cartridge heaters, they are installed outside the die. They also utilize a resistance wire to heat up the plastic mould. They usually are flat or arch-shaped.

- Cast aluminium heaters

Figure 7: Cast-aluminum heaters

Figure 7: Cast-aluminum heaters

Cast heaters are usually embedded into the extrusion die mould. Due to their high surface area, they provide more uniform heating. They are also used to heat the extruder’s barrel.

Conclusion

In this chapter, we have introduced plastic dies, seen their design and operation. And talked about how the coat-hanger sheet mould works.

Next, we’ll dive more into types of extrusion moulds that we can produce for you at Benk Machinery.

Chapter 2: Types of plastic extrusion moulds we make

Quality is at the forefront at each die we make at our factory. All dies are made from GB 40Cr steel—one the most widely used steel-alloy grades for gears, pins, shafts, etc.

GB 40Cr has the best range of mechanical properties. For instance, its high-hardness and toughness allow it to withstand wear.

It also has a high-surface finish and can be easily galvanized—(coating with a second metal layer like zinc).

Interchangeable parts such as the die land and pins are galvanized. The protection layer can last upwards of one year, after which, they have to be re-coated to extend their working life.

Another quality measure is using the best temperature controllers from the Omron brand.

2.1 Plastic pipe mould

Figure 8: In-line tube die head

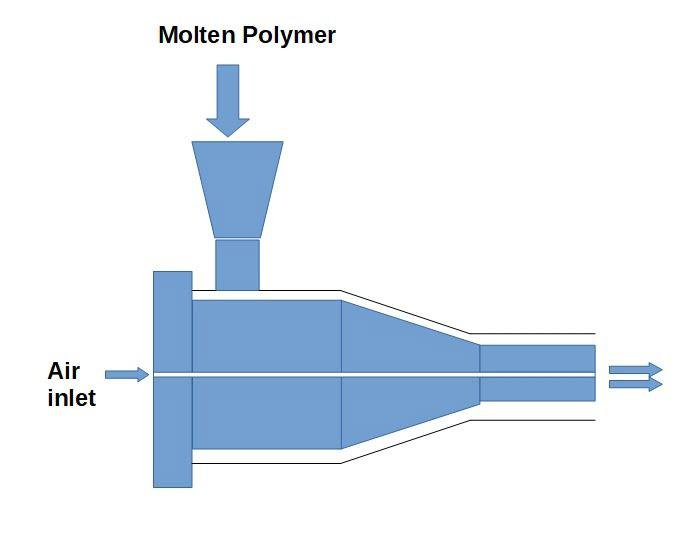

Plastic pipe dies shape the extrudate into a ring-shape/annulus structure. They are two main types of pipe dies:

- In-line dies

Figure 9: In-line die

Figure 9: In-line die

In this type, the die is at a straight line with the extruder. In the above diagram, the molten polymer enters from the left (upstream die side).

It’s mounted on the barrel using the die flange (9) and the housing (1) supports all the components of the die.

As the molten enters, it’s distributed by the (2) torpedo shaped mandrel. From the mandrel, the molten polymer flows into the die land (4).

It sets the outer diameter of the pipe. It also has a bearing on the pipe’s surface finish.

The die land is held in place by the retaining plate (5), which is connected to the die’s housing.

The mandrel is suspended at the center of a circular channel with the mandrel support (8).

In a spider die, there are more than one mandrel supports called spider legs.

Inside one of the mandrel supports, there will be an air hole (7). The air hole provides a slight air pressure inside the annulus extrudate shape to keep its malleable walls from collapse.

Figure 10: Example of flange.

What happens when you want to manufacture pipes with a different OD and thickness?

When you wish to create pipes of a different outside diameter, all you need to do is adjust the die land’s gap with the centering bolt (6) and use a different die pin.

When you want to create pipes of different wall thickness, you just adjust the die land’s distance while using the same die pin (3).

Finally, we have the heating band (10) that maintains the die at operational temperatures.

- Cross-head die

Figure 11: Simple illustration of a cross-head die

The inline die is the most popular die type. However, it’s still prone to the formation of weld lines.

An improvement to the inline die design is the crosshead die. The melt is introduced into the mandrel through side feeding at 90 degrees.

The melt is not split due to the absence of spider legs. Instead the mandrel is mounted on the die housing inline as shown in the diagram. It’s not widely used to its higher cost.

Distribution types for in-line dies

There has been continuous improvement in the design of pipe moulds. Several distribution mandrel types have emerged including:

- Spiral mandrel – The distributor resembles a screw. This design has been was widely used in blow film extrusion and was adapted for tubes since its less prone to weld lines.

- The Lattice-basket type – It’s used in high output lines.

- Rotary inline dies

You might encounter other distribution types. But all you need to know is the difference between an in-line die and cross-head die.

2.1.1 PVC pipe mould

At Benk, you can get a PVC pipe mould with one exit or multiple exits. We supply adapters for die lands and pins.

Figure 12: Double outlet plastic pipe mould

For one exit, our PVC pipe mould can produce tubes of 16-800mm OD. The two exits PVC pipe die can produce pipes from 16-160mm OD.

Our four cavity PVC pipe extrusion line that can produce pipes of 16-32mm OD. Dies with multiple exits take advantage of the production capacity of extruders for large diameter pipes.

Benk also supplies a PVC pipe mould for a three-layered PVC pipe. Learn more about the PVC pipe manufacturing line

2.1.2 HDPE pipe mould

Our HDPE pipe mould makes solid wall pipes with size ranges 16-1200mm OD. It works with high-speed and normal speed lines.

The HDPE pipe mould has a specially designed mandrel since it takes two melt streams; one from the main extruder that supplies the melt for the pipe’s structure; and the second smaller extruder for marking. We can customize the die to produce 1 to 4 lines on the pipe.

Figure 13: Lattice-basket die for HDPE pipes.

Learn more about our solid wall HDPE extrusion machine:

2.1.3 PPR pipe mould

Our PPR pipe mould can produce pipes with a diameter of 16-160mm. We also have a double outlet PPR pipe mould with OD from 16-110mm.

Since PPR pipes have marking lines, the mould has a special mandrel design to combine the two melt streams.

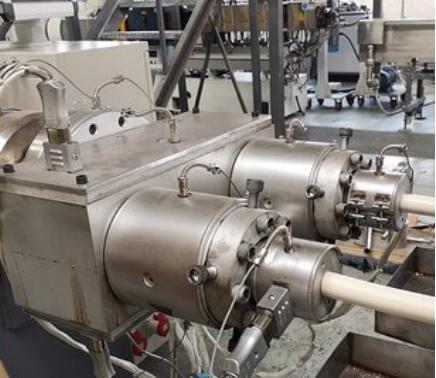

Figure 14: PPR mold with marking line extruder

If you’re interested in the PPR mould, you can learn more about it line here.

- Corrugated pipe mould

There are two corrugated pipes types; single wall corrugated pipe and double wall corrugated pipes.

Our single wall corrugated pipe mould can produce pipes from 16-63mm OD used as electrical cable conduits.

Double wall corrugated pipes are co-extruded using two single-screw extruders. Our double wall corrugated pipe mould makes pipes with a size range of 50-1200mm OD.

To get the corrugated structure, the pipe will pass through a forming machine with corrugated moulds.

Figure 15: HDPE pipe mould showing molding blocks

Figure 15: HDPE pipe mould showing molding blocks

You can learn more about the line here.

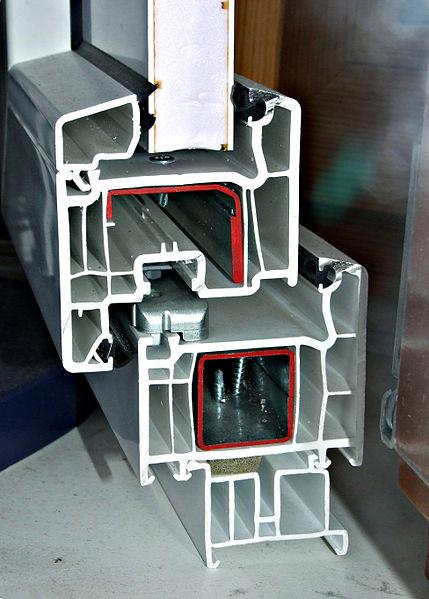

- Plastic profile mould

Plastic profiles are complex shapes. Unlike sheets or pipes that have regular geometric or concentric shapes, profiles are irregular such U shapes, L shapes and complex shapes such as window profiles.

Figure 16: Plastic window profile

Plastic profile molds are also the most complicated to manufacture. Due to their irregular shapes, there is more variation in the flow velocity of the melt polymer as it fills up the mould.

The design of the mould has to achieve consistent flow. One design consideration may be using flow resistors where the flow is too fast.

It generally takes a lot of research and testing to develop plastic profile moulds. That’s why you should get your plastic profile mould from an experienced manufacturer like Benk.

Now let’s look at the plastic profile moulds we make:

- PVC/WPC window profile mould

The PVC and WPC profile mould are employed in the manufacture of window profiles. We can supply different mould sizes to make profiles of different sizes. You can find out more about the window profile line here.

- WPC/PVC door board mould

Our door board mould for wood-plastic composite and PVC doors produces hollow boards with a thickness of 40mm.

It can produce widths of 600mm, 800mm and 1000mm. You can also customize the width of the door board.

Figure 17: Plastic mold for boards

You can learn more about the WPC/PVC door board mould here.

- PVC ceiling mould

Benk’s PVC ceiling mould can produce boards with widths of 150 to 600mm. You can also control the thickness and widths to fit your needs. Check out our PVC ceiling line.

- WPC/PVC wall panel mould

Our wall panel mould will make panels used in construction applications like indoor decorations. The wall panels can have widths of 300mm, 400mm, 500mm, and 600mm, which are the current standards in the market.

The plastic mould is designed to work with PVC material that has a higher calcium content.

For PVC-wood panels, the mould can make squares hollows. And for PVC stone panels, it can produce a core with round holes. You can learn all about this production line here.

- Plastic sheet mould

The plastic sheet mould is also called the “plastic sheet die” or “slit die.” We saw the main parts in chapter one. Here we will talk about the different ways the melt is distributed by the manifold:

T-Die

The melt is distributed in a “T” shape. The molten polymer will enter at the center of the “T”, then get distributed to the left and right side.

T-dies have a low-pressure drop, however, they are prone to material hang-up or arching (a phenomenon where the melt stagnates at the ends).

Fish-tail

With the fishtail design, the distribution resembles a fish-tail shape that’s different from the T-die’s 90-degree angles. This shape minimizes the stagnation of the material at the corners.

Coat-hanger dies

The coat-hanger die is widely used and looks just like like a coat-hanger. It’s the most common die for sheets.

Figure 18: Illustration of coat-hanger die

Figure 18: Illustration of coat-hanger die

- Stone plastic composite sheet mould (SPC sheet mould)

Figure 19: T-die for sheet mould

The SPC sheet mould makes sheets with a thickness of 2-8mm and width of 1220mm. It’s very durable and can be in production for over 10 years. Some of the products you can make with the stone plastic composite sheet mould include

Luxury vinyl tile, WPC flooring, luxury vinyl plank, and stone plastic flooring. You can learn more about it here.

- PP hollow sheet mould

The PP hollow sheet mould manufactures sheets with a thickness of 0.5mm to 30mm with a diameter of 1000 – 2800 mm.

Figure 20: PP hollow sheet die

It’s a T-die. PP sheet dies have flute-structure, so the lips of the die have rice-shape, square-shapes and so on. Two or more extruders can be combined in a multi-manifold die to make sheets with up to 5 layers.

Figure 21: PP hollow sheets

Figure 21: PP hollow sheets

- Board mould

Our T-type board mould can produce boards with a thickness of 5-20mm and width of 1200mm. But you can adjust the board mould to match your needs.

You can either use PVC or WPC material and produce non-foam boards and foam-boards.

Learn more about our plastic board production line.

Chapter 3: Get the Best Plastic Extrusion Mould at Benk Machinery

3.1 Plastic extrusion mould cost

Basically, extrusion moulds can range from US$1,500 up to $10,000 depending on the supplier.

The best way to find out about the plastic extrusion die cost is to talk to the supplier directly. Dies will consume different amounts of material based on their design.

At Benk, we will make sure to give you the lowest cost, and the best quality & value for your investment.

3.2 Where can one purchase a custom plastic extrusion mould?

You should purchase a mold from an experienced plastic mould manufacturer. When you purchase the die, it should be customized based on the characteristics of your resin.

The melt will be very sensitive to the design of the die. The shear thinning and elastic behavior of the melt have to accounted for in the design.

The supplier must also have a professional design team with a good reputation.

Benk Machinery meets all these requirements. Not only do we use high-quality steel, but it’s also heat treated, and we employed high-tech machining. We also stock and supply spare parts readily for items such as die pins. You’ll get a guarantee on your purchase and timely delivery in less than 30 days.

3.3 How to find reliable plastic extrusion mould from China?

Most customers worry about finding a quality supplier from China. Ask these questions to ensure you get a good supplier.

Inquire if the company holds a valid business license and if the products have certifications like the SGS certificate.

Ask about the companies the supplier has worked with. Also, verify the supplier’s location, and also inquire if can plan a visit to the factory.

The supplier should also be willing to test all the machines before shipment.

Chapter 4: How to solve the problem in your plastic extrusion mould?

Figure 22: 4-cavity die showing the manifold section

4.1 What are the normal problems on extruding mould?

Due to the complex workings of the plastic extrusion mold, there are several problems that can arise. Some include:

- Die swelling

Die swelling demonstration:

Die swelling occurs when extrudate expands as it leaves the die lips. This is abnormal since the extrudate dimensions have been set by the die cavity.

For instance, the tube might have a larger diameter than that of the annular cavity. Die swelling has been attributed to unification and velocity relaxation of the melt.

- Weld lines

They occurs in annular spider dies where the melt is split and rejoined to form the tube. Improved designs like the lattice basket die and cross-head mandrel can eliminated this problem.

- Screw turning memory

This problem is usually easily solved by extending the time the melt spends in the die. It’s done by increasing the length of the die, which removes the previous memory.

4.2 Plastic extrusion die troubleshooting

Plastic extrusion mould troubleshooting is the process of identifying and trying to solve die problems. Here are some tips to make this process successful:

- Gathering process data

During normal runs, the operator will record and collect processing data such as temperatures, pressure, etc in a database. When problems occur, they will compare the historical data with the current data to identify abnormalities.

For instance, the operator will compare the temperature readings in the extruder, melt pressure, the screw’s rpm.

The operators should also maintain detailed and timely maintenance records. They should also have experience and technical knowledge of the extrusion process.

- Calibration

Instruments have to be checked for accuracy. For instance, the operator must ensure that the thermocouple is giving the right reading.

It’s recommended to calibrate the instruments & sensors used for pressure, temperature, RPM and other readings at least two times during the year.

- Resin changes

It’s very important to keep the resin composition consistent. Any changes in the resin will affect its flow characteristics and behavior in the die.

It’s also important to monitor the storage area and keep it clean and dry. Materials must also be checked for quality after they arrive at the factory by running chemical and physical tests.

- Wearing

Some problems may also occur if the components of the die have become worn out. Regular maintenance should be done at least once every year or when the product quality starts waning.

- Design considerations

The design of the die can also be a source of the problem if it wasn’t made correctly. The screw may also be mismatched with the die. They might be issues with a particular temperature zone in the extruder.

Other problems may be can be solved by increasing the die channel, increasing or lowering the temperature in the die, or varying the extruder’s output.

4.3 Plastic Extrusion Die Cleaning

After production, die cleaning is a necessary but tricky process that requires expertise. Keeping the inner surfaces cleaning will keep the die performing for a long time and ensure high yields.

Die cleaning doesn’t mean that you have to dismantle the entire die. The die might be disassembled only once or twice per year (“split-and-clean” ) as part of the regular maintenance. For instance, in a sheet die, the die bolt may be unfasten the upper die plate removed.

On-line cleaning is usually done during normal production. Here is a demonstration of the cleaning process of PP Hollow Sheet Mould:

The operator is wearing heat-resistant gloves to grab the plastic extrudate and pull it away. It’s very essential to pull at the right rate to avoid it from tearing and getting stuck inside.

An air hose is used to blow air where the melts adhere to the metal surface. The operator then uses a brass/copper tool to remove the remaining polymer from the die lips so as extrudate’s flow is not obstructed.

We use copper tools since they are soft and don’t damage the sensitive surface of the mould.

Conclusion

Benk is the best company for your all your plastic extrusion mould needs. Let our professional design team work with your company.

We utilized complex modeling of flow processes, computation techniques, and continuous R&D to develop the best mould designs for our clients.

To make the best mould for you, we only need to know the nature of your recipe, production line speed, extruder’s capacity & output.

Feel free to contact Tony with your request. We’ll quickly get back to you in less than 24 hours.

References

- Reference M. M. Kostic and L. G. Reifschneider, “Design of Extrusion Dies,” pp. 633–649, 2006.

- Effective troubleshooting of extrusion problems

- How to Split & Clean Flat Dies