Belling Machine

| Electrical Parts | CHNT brand |

| Motor | Simens motor |

| Temperature Controller | Omron brand |

| Inverter | ABB brand |

| Screw and barrel | Best quality from China |

| Heater | Long service life |

| Gearbox | Jiangying Gearbox |

| Your requirements | We make machine as per ur demands |

Your Premier Belling Machine in China

BENK belling machine also named PVC pipe socketing machine which used to bell the mouth of pipe, then we can connect pipe with pipe, benk PVC pipe belling machine always to be together with PVC pipe extrusion line in order to bell pipe online.

BENK is Chinese belling machine manufacturer, our stocketing machine has good prices with trustworthy quality, as we always recommend the PVC pipe stocking machine to our clients who want to buy PVC pipe extruding machines from us.

BENK produce two types of PVC pipe belling machine which is made as per your PVC pipe production line, if your PVC pipe production is double pipe extrusion line, we will use double pipe belling machine, otherwise, we will use single pipe belling machine.

BENK PVC pipe socket making machine has two type of mould which is R type and U type, many customers would like to choose U tyre as its price is cheaper, if you need R type, it is a little expensive, but the same price of the belling machine.

BENK use two ABB inverter and stainless steel heater in our PVC pipe socket machine, it can work stably and save power for you, we also can adjust the working speed of the machine in order to conformity to the speed of pipe extrusion.

- Data Sheet

- Videos

- Send Enquiry

| Model | Pipe Diameter | Heating Method | Belling Method | Heating power | Dimension |

| SGK110 | 50-110mm | Electric heating | Mould physical expansion | 10.5kw | 7500x1400x1750mm |

| SGK160 | 50-160mm | Electric heating | Mould physical expansion | 10.5kw | 7500x1400x1750mm |

| SGK200 | 50-200mm | Electric heating | Mould physical expansion | 10.5kw | 7855x1350x1900mm |

| SGK250 | 110-250mm | Electric heating | Mould physical expansion | 10.5kw | 7830x1620x1700mm |

| SGK315 | 160-315mm | Electric heating | Mould physical expansion | 14kw | 8050x1750x1900mm |

| SGK450 | 200-450mm | Electric heating | Mould physical expansion | 18kw | 8290x2090x2080mm |

| SGK500 | 315-500mm | Electric heating | Mould physical expansion | 18kw | 8500x3050x2100mm |

| SGK630 | 400-630mm | Electric heating | Mould physical expansion | 22.5kw | 8615x3125x2500mm |

Belling Machine: The Importers Guide

PVC pipes have to be joined together when they are installed. There are several joining methods including solvent-cement welding, heat fusion and the belling/socketing process.

The cheapest and fastest way is the belling process. For these reasons, it’s the most popular joining method.

At Benk Machinery, up to 80 percent of customers who purchase our PVC pipe production lines, also buy a belling machine. It’s simple since the machine can be easily integrated into the main line, and the customers save energy & time.

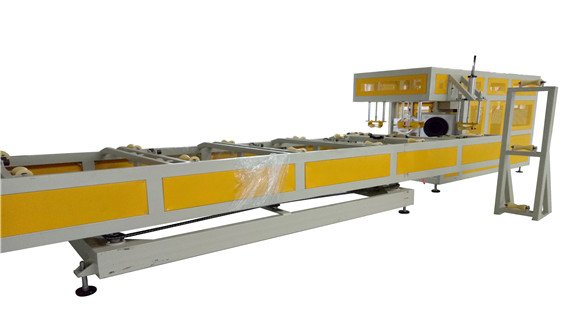

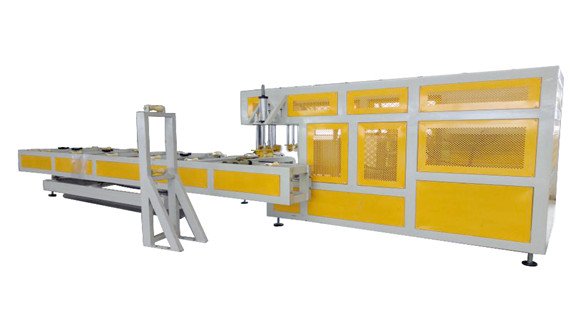

Figure 1: Automatic belling machine

But if you’re looking for pipe belling machine manufacturers, you’re in the right place.

We’ll share our knowledge on belling techniques. The features of our automatic belling machine will also be covered.

By the end, you’ll have the know-how to choose the most-suitable product:

Chapter 1: Introduction to Belling

1.1 What is belling?

Figure 2: Example of solvent welding

Figure 2: Example of solvent welding

- Definition

Belling is the process of heating the end of a PVC tube and expanding its diameter using a mold.

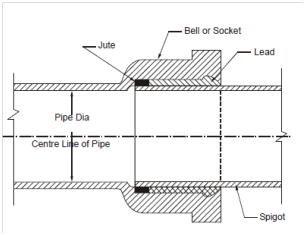

The enlarged end is called a bell, socket or the male-end. The other end is the spigot or the female.

Figure 3: Diagram showing spigot and bell

Performance of the joint formed between the spigot and bell is vital. You don’t want ground water or surrounding soil to infiltrated into the pipe. Water leakages must also be avoided.

Joints are strengthen using various techniques; an adhesive may be applied or a gasket may be installed inside a grooved bell to form a seal with the spigot.You’ll understand this further when we talk about belling techniques.

1.1.2 When is belling done?

The PVC production line consists in order, an extruder, shaping die, vacuum calibration tank, cooling bath, haul-off, and cutter.

The belling machine comes at the end. If you opt for an automatic belling machine, it will be installed on-line.

In the online belling process, the pipes are automatically fed into the PVC belling machine.

A manual belling machine will have to be operated by at least two people.

1.1.2 Principle behind the belling process

There are two kinds of plastics; thermosetting plastics that are permanently set and can’t be re-melted; and thermoplastics that can be re-melted and molded again.

PVC is a thermoplastic, so after the pipes are cooled in the cooling bath, you can still heat and expand them.

1.2 Pipe bell styles

1.2.1 “U” belling style

Figure 4: U-belling Style

It’s done by heating the pipe, then inserting it into a plain socket mould with a slightly larger diameter.

PVC pressure pipes of OD 16mm, 20mm, 25mm, 32mm, 40mm and 50mm undergo U-belling.

During jointing, an adhesive may be used to strengthen the connection.

1.2.2 “R” belling style

Figure 5: R-type belling

Figure 5: R-type belling

Do you notice any difference with the U-belling type? There is a groove inside the bell. Next, you might see a black gasket.

Gaskets made from synthetic or natural rubber enhance the pipe’s sealing capacity. Most of the times, the gasket is installed separately.

- type belling is adopted for pipes with an OD from 63mm to 630mm.

Glue is not needed to join the pipes. The spigot end is lubricated and forced into the bell, until the reference mark is reached. The lubricant must be soluble in water, and not affect the gasket’s performance.

Here is a video showing installation of PVC gasket sealed pipes.

https://youtu.be/OS22GjI-k4A

There are two types of gaskets:

- Non-reinforced and homogeneous gaskets – Made from one type of material and are not strengthened.

- Locked-in gaskets – Gaskets reinforced using a steel ring. They are usually referred to as Rieber gaskets invented in the 70s by an engineer by the name Gunnar Parmann, who was working for the Rieber and Son Plastic-Industri A/S of Bergen, Norway

Rieber gaskets are installed during the belling process, and are permanent. Why were they developed?

To prevent a phenomenon called “fish-mouthing”, where gaskets may become dislodged as the spigot is forced into the bell, and to increase the sealing performance of the joint.

1.2.3 Square type

Figure 6: Square-type

Figure 6: Square-type

The square type is another PVC belling style similar to the R-belling style. But the groove has a rectangular shape instead of an asymmetrical shape.

1.3 PVC pipe belling machines

1.3.1 Automatic belling machine

In this video, you can see the automatic belling machine in action as we test it in our factory.

The Online belling process technology:

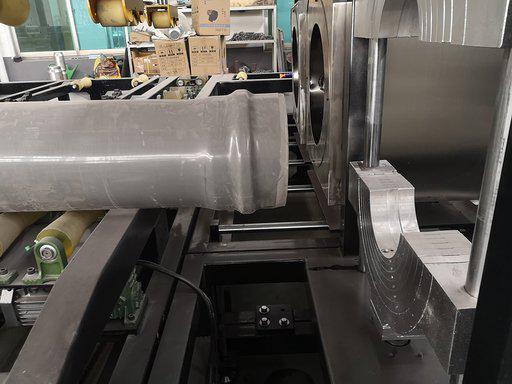

Figure 7: Pipe moving across the machine

A previously cut pipe is guided into the receiving station by a series of rollers. Using a chain convey, the pipe is lifted and moved across the machine’s surface to the first heater station.

Figure 8: Pipe entering the belling station

Figure 8: Pipe entering the belling station

A continuously rotating belt rotates the pipe inside the heating oven. Heat softens the end of the pipe. The pipe is then moved using the chain conveyor to the belling station.

Figure 9: Clamps grasping pipe to move into the belling station

Figure 9: Clamps grasping pipe to move into the belling station

Two clamps grasp the pipe and move it into a belling position. A hydraulic powered mandrel inserts the mould into the pipe. To form a groove for the R belling style, the expandable inserts on the mechanical mould expand.

Cooling comes next. Cold circulating water is sprayed on the pipe’s surface.

Air cooling may be used, but water cooling is preferable for pipes with a thick diameter that don’t cool quickly in air.

After cooling, the mould is retracted, and the clamps open. The pipe is then withdrawn from the belling station for stacking.

1.3.2 Manual/semi-automatic belling machine

The manual belling machine differs from the automatic belling machine in that it lacks a chain convey system to move previously cut pipes into each belling station.

So two operates are need, one to feed the pipe into the heating station, and the other to feed the pipe in the belling station, and for stacking it.

Conclusion

In this chapter, we have looked at PVC belling styles and talked about the automatic and manual belling machine.

Next, we’ll talk about the parts and benefits of our automatic PVC pipe belling socket machine.

Chapter 2: Features of Our Belling Machine

2.1 Main parts

2.1.1 Feeder device

Figure 10: Finished R socketed PVC pipe

The feeder device is supported by the frame, and it moves the pipe horizontally. Our feeder device is stable and very accurate

2.1.2 Heating

We use electrical heaters in our PVC belling machine. They heat the pipe using contact heating by means of an aluminium block.

This heating method is very precise as only the portion that forms the bell is heated.

Figure 11: Cast Aluminum Heaters

An alternative method of heating is infrared heating with short wave heaters. It is usually used for smaller pipes.

You can have more than one heating oven in a PVC pipe expanding machine depending on the level of softening required.

We only need to know more about your products to recommend the number of heaters you’ll need.

2.1.3 Mould

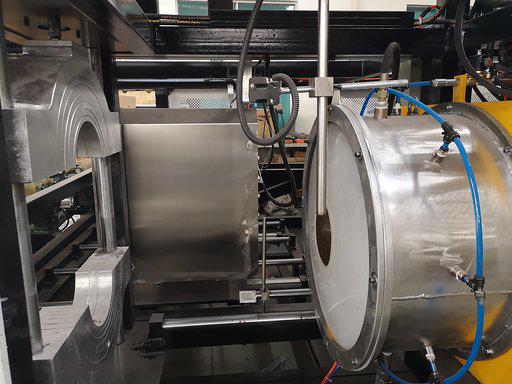

Figure 12: Belling station with water cooling sytem

There are different types of moulds as we saw earlier. For U type belling, you only need a plain mould.

For R type belling, we use a mechanical mould with collapsible and expandable inserts used to form the groove. We can supply molds of different sizes that are easily interchangeable.

Figure 13: Belling moulds with expandable inserts mechanism

Figure 13: Belling moulds with expandable inserts mechanism

2.1.4 Cool water spray system

We use circulating water to spray cool pipes after forming. The water jets are mounted on the belling station.

Once the pipe cools, it cannot be transformed easily. Alternatively, air may be blown on the surface of the pipe to cool it.

2.1.5 Hydraulic components

Figure 14: Hydraulic power unit

Hydraulic systems use an incompressible fluid to transmit force from one point to another in order to move a mechanical part.

Figure 15: Hydraulic station spare parts

In the automatic belling machine, the hydraulic components includes the cylinder used to grasp the heated pipe in the belling station. Moving the mould is also accomplished by the hydraulic system.

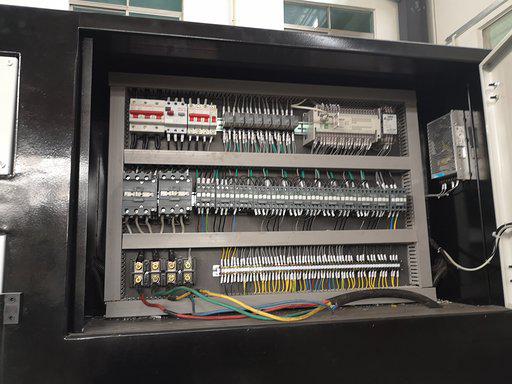

2.1.6 Electrical components

Figure 16: Electrical cabinet showing power supply cable, contactor etc.

Figure 16: Electrical cabinet showing power supply cable, contactor etc.

The main electrical components of the belling machine include the control components that adopt PLC control and the power supply.

There is a Siemens panel/touch screen that allows you to access all controls of the machine, and preset them so that it can work automatically.

Figure 17: Control panel

2.2 Advantages of our PVC pipe belling machine

If you choose our belling machine for PVC pipe socketing, you will get a number of advantages:

- It has an efficient energy consumption, which will consequently lower your electrical bill and operating costs.

- We use parts are from famous international brands.

- It can produce two belling styles in one machine. The “U” and “R” types.

Figure 18: Inside the belling device

- The automatic belling machine can be incorporated into a working line, or used separately.

- We provide a wide range of moulds sizes from OD 20mm to 630mm.

Figure 19:R type molds

- With a multilingual touch screen, it’s simple to learn how to program the machine, which translates to less time spent training the operator.

- Our pipe belling machine adopts advanced technology, and is carefully crafted for durability. It remains in good condition even after many years of use.

- The belling machine has a strong frame assembled by welding cold-drawn steel pipes.

Figure 20: Frames used to make belling machines

- We can easily customized the machine based on your special specifications, for instance, we can supply the PVC four pipe belling machine.

Figure 21: PVC four pipe belling machine

- We can guarantee the quality of the belling machine since we make it at our workshop.

Chapter 3: Technical Parameters

| The diameter of PVC pipe(mm) | 50-160 | 110-250 | 250-400 | 315-500 | 400-630 |

| Applicable wall thickness(mm) | 2.9-9.5 | 2.9-15 | 4-23.7 | 5-29.7 | 9.8-24 |

| Cooling type | Fan or water cooling | Fan or water cooling | water cooling | water cooling | water cooling |

| Output | 2-40pipes/hour | 2-40pipes/hour | 2-30pipes/hour | 2-25pipes/hour | 2-15pipes/hour |

| Socket type | Solvent ,Rubber-ring expansion or rubber-ring lip type | ||||

| Operation type | Automatic or manual | ||||

| Discharging type | Automatic | ||||

| The heating control | Heating adjustment available | ||||

Model |

Pipe Diameter | Heating Method | Belling Method | Heating power | Dimension |

| SGK110 | 50-110mm | Electric heating | Mould physical expansion | 10.5kw | 7500x1400x1750mm |

| SGK160 | 50-160mm | Electric heating | Mould physical expansion | 10.5kw | 7500x1400x1750mm |

| SGK200 | 50-200mm | Electric heating | Mould physical expansion | 10.5kw | 7855x1350x1900mm |

| SGK250 | 110-250mm | Electric heating | Mould physical expansion | 10.5kw | 7830x1620x1700mm |

| SGK315 | 160-315mm | Electric heating | Mould physical expansion | 14kw | 8050x1750x1900mm |

| SGK450 | 200-450mm | Electric heating | Mould physical expansion | 18kw | 8290x2090x2080mm |

| SGK500 | 315-500mm | Electric heating | Mould physical expansion | 18kw | 8500x3050x2100mm |

| SGK630 | 400-630mm | Electric heating | Mould physical expansion | 22.5kw | 8615x3125x2500mm |

Chapter 4: Socket belling machine for PVC pipe in China

Figure 22: After tested 500mm PVC pipe socketing machine

4.1 What is the belling machine price?

The cost depends on the model you plan to buy. The number of units per order may influence the purchase price.

R type pipe expanding machine also costs more than the plain socket U type machine. Likewise, the automatic belling machine is more expensive than the manual type.

Generally, the machines range from US$8,000 to US$20,000. If you want to buy a new belling machine online at the most affordable price in China, just contact us and tell us about your requirements.

We will offer you the best combination of durability, performance, reliability and value.

4.2 Buying PVC belling/socketing machine – What to expect

Benk Machinery ensures that our clients get the best results from our machines by offering them quality support and guidance services.

We start by offering free consultation. Our professional team pays close attention to your special requirements and recommends the most suitable models.

After you make the decision to purchase the PVC belling machine, we’ll prepare an offer. Once you accept it and sign the contract, we will start making the machine for you.

Figure 23: Making pipe belling machine at our workshop floor

Figure 23: Making pipe belling machine at our workshop floor

We can also offer engineering layouts for your factory. When the machine is ready, we can send you the pictures. All our machines are tested before they are packed in wooden panels for shipment.

An engineer can accompany the machine and help you install it at your factory. They can also provide training to your first line operator.

Should you encounter any challenges, our technicians can offer online video support or on-site servicing.

Conclusion

Figure 24: Four pipe belling machine for smaller pipes

Contact us today, our professional team is ready to help you find the most suitable belling machine. We can also supply a PVC pipe production line including the twin screw extruder and other auxiliary machines like the high-speed mixer.

If you are not sure what model suits your needs, talk to our manager Tony, who will gladly assist you.