What are Thermoplastic Elastomers?

Thermoplastic Elastomers or Thermoplastic rubber, abbreviated as TPE/TPR, also known as artificial rubber or synthetic rubber, exhibit the properties of traditional vulcanized rubber at room temperature: high elasticity, aging resistance, oil resistance, etc. Meanwhile, after heating, they possess the processing characteristics of thermoplastic materials, allowing easy molding through processing methods such as injection molding, extrusion, and blow molding. They combine the dual properties of traditional vulcanized rubber and thermoplastic materials.

Characteristics of the Thermoplastic Elastomer Industry

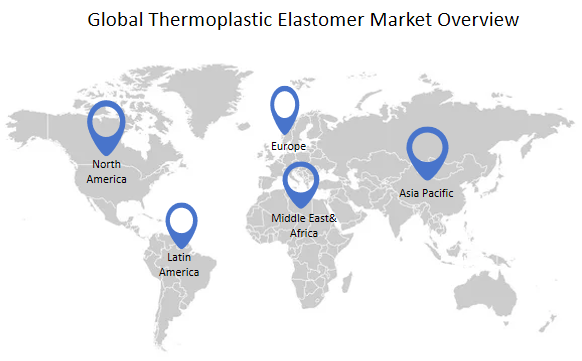

Distinct Trend of Regionalization

With different countries and regions focusing on research and production in the field of TPE, the TPE industry on a global scale shows obvious regional trend characteristics, leading to a diversified industrial development landscape.

Asian Market Shows Cost Advantages and Scale Benefits

Regarding industrial distribution, the TPE industry in Asia boasts cost advantages and scale benefits. China is one of the world’s largest producers and consumers of TPE, occupying a significant share of the global market. China’s TPE industry is concentrated in the Pearl River Delta, Yangtze River Delta, and Bohai Rim regions, which possess advanced manufacturing bases and are close to major consumer markets.

European Market Focuses on Environmental Protection and High-Value-Added Products

The TPE industry in Europe emphasizes sustainable development and environmental protection. By adopting eco-friendly materials to reduce production energy consumption, and optimizing production processes and industrial chains, the industry has demonstrated strong competitiveness in the automotive and electronics industries in terms of TPE material applications.

North America Leads the Way in Innovative Technologies

With innovation driving the development of the TPE industry to a mature level, North America pays more attention to technological research and development. In the application of TPE materials, they are widely used in the fields of automotive, medical, and consumer goods.

Latest Forum on Thermoplastic Elastomers

The 9th Technology and Market Development Forum Of the Thermoplastic Elastomer Industry

On September 27, 2024, the 9th Thermoplastic Elastomer Industry Technology and Market Development Forum was held in Ningbo, Zhejiang Province, China. With the theme of “Innovating for New Materials, United for a Winning Future,” the forum brought together numerous experts, scholars, and industry representatives from the thermoplastic elastomer industry. The forum conducted in-depth exchanges and discussions on various aspects of thermoplastic elastomer material research and development, applications, and future development trends.

In terms of technology, the forum focused on topics such as scientific formulations, research directions, and innovative development dynamics of TPE. In terms of the market, the forum analyzed the current application status and future development trends in the technical field of the TPE industry, sharing insights on the application prospects of TPE materials in related industrial chains such as medical, synthetic leather, and wire and cable industries. Additionally, the forum conducted in-depth discussions on the transformation and upgrading of the thermoplastic elastomer industry, as well as its green, low-carbon, and high-quality development.

Development Plan for Thermoplastic Elastomer Products

The discussions at the forum have provided us with in-depth insights into the current status and future trends of the TPE market, as well as innovative application cases of TPE in various fields. This cutting-edge technological information not only enriched our knowledge base but also provided technical references and inspiration for our upcoming new thermoplastic elastomer products. We are now incorporating these advanced technologies into our product development to enhance product performance and market competitiveness. Furthermore, in our future product development, we emphasize environmental protection and sustainable development by adopting more eco-friendly materials and production processes to reduce the harm to the environment.

Outlook and Future of the Thermoplastic Elastomer Industry

Broad Market Prospects

TPE finds applications in multiple fields, particularly in new energy vehicles, smart homes, medical devices, and other sectors. The demand for thermoplastic elastomer production will increase significantly, and the TPE industry will maintain a continuously positive trend in the future. We will seize the opportunity to expand the processing and application fields of thermoplastic elastomers to meet market demands. Customized solutions tailored to specific application needs will also become an important direction in our strategic planning.

Further Innovation in Technology

Due to its dual properties of rubber and plastic, TPE possesses unparalleled superiority in applications. We will optimize production processes, strengthen technological innovation, and enhance the performance of TPE to improve its properties such as heat resistance, lightweightness, and resilience.

Cost Efficiency

Compared to traditional materials, TPE allows for 100% direct reuse of scraps after being crushed, reducing resource waste and waste disposal issues during production. With its recyclability and environmental performance, the cost structure of the TPE industry will be optimized and upgraded, enhancing economic feasibility.