Plastic Extrusion Machine

BENK plastic extrusion machine also named plastic extruder machine which includes single screw extruder, conical twin screw extruder, and parallel twin screw extruder, our extrusion line is used to make different plastic extrusion products, such as PVC profile, plastic board, plastic panel plastic corrugated pipe, plastic granules, wood plastic composite and wood plastic profiles and so on.

Benk is a leading plastic extrusion machine manufacturer in China, we have served many big plastic extrusion companies in the world, our advantages is that we always supply PDF drawing and production process for our extrusion machine process before customers confirm their orders, as they can understand our plastic extrusion machines’ work and process steps very well.

Benk is not the biggest plastic extrusion machine company in China, but we always try our best to supply super quality machines with good prices and also try to save cost for clients with our advanced ways and technician.

Usually, one extruder or extrusion line at least need one operator to maintain the machine to be on stable production, we also will supply training after buying our machine, and your staffs can learn how to maintain it.

Just tell us which products do you want to produce, then our top sales and engineer will assistant you to build up your factory to produce plastic extrusions.

Extruder or The Whole Extrusion Line, Benk Can Always Satisfy You

Why Big Brand Trust BENK MACHINE

Why Benk Machine

BENK has been in making plastic extrusion machines industry more than 10 years, our engineer and staff most come from big extrusion machine companies, such as Beier, jwell…

Our sales has been worked in plastic extrusion machines more than 15 years, they can give your satisfied answer for all problems for your current extrusion machines or the plastic extrusions you want to make.

Single screw extruder is used for PE/PP/PPR pipe extrusion line or PE/PP pelleting production line.

Conical twin screw extruder is used in PVC pipe production line, PVC profile production line, PVC door board production line, WPC profile production line, PVC marble sheet extrusion line, SPC floor production line and PVC foam board extrusion line.

Parallel twin screw extruder is almost used in compounding extrusion line, such as WPC compounding, masterbatch pellets…

Helpful Resource To Support Your Business

Plastic Extrusion Machine: The Complete Buying Guide

In the Plastic industry, a plastic extrusion machine plays a significant role.

As such, you need to understand the details of a plastic extrusion machine.

Here is a guide that will help you to understand these details.

You will be able to understand the working principles of a plastic extrusion machine as well as its design.

Not forgetting where you can apply this machine.

To understand this and much more, let’s keep reading.

- What is a Plastic Extrusion Machine

- Plastic Extrusion Machine Basics

- Parts of a Plastic Extrusion Machine

- Technical Specifications of the Plastic Extrusion Machine

- Working Principle of the Plastic Extrusion Machine

- Applications of the Plastic Extrusion Machine

- Support Equipment for a Plastic Extrusion Machine

- FAQs on the Plastic Extrusion Machine

- Conclusion

What is a Plastic Extrusion Machine

Before we start off, let’s define what a plastic extrusion machine is.

A plastic extrusion machine can be defined by understanding what plastic extrusion is.

This is a manufacturing process that involves plastic raw materials in the form of resins or pellets.

The resins are mixed with other ingredients such as colors and melted. The molten product forms a continuous profile from which you can make a variety of plastic products.

The machine that does this is the plastic extrusion machine.

Plastic Extrusion Machine Basics

I believe that now you have an idea of what a plastic extrusion machine is. The next step is getting to know the basics of this machine.

This includes why you need to acquire this machine as well as the benefits of having it.

Also, I will take you through the limitations of the plastic extrusion machine.

Have a look.

Why you Need a Plastic Extrusion Machine in Plastic Processing

Perhaps one of the important questions you need to answer is why do you need a plastic extrusion machine. Well here are some of these reasons:

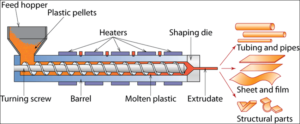

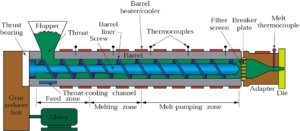

Figure 1 Plastic extrusion process

Plastic extrusion machine helps in improvement in agricultural productivity

With the increase in food demand, we need to be innovative in the way we produce our agricultural food.

This is easy with the help of the plastic extrusion machine.

For instance, irrigational pipes, as well as sprinklers, can avail water in the farm which ensures continuous productivity

Also when you look at the greenhouse, there is a need to have light.

There is a special plastic sheet which can act as greenhouse roofs. This sheet ensures some degree of light to pass.

1. Manufacture of sewer pipes

You can avoid certain diseases by ensuring that you dispose of human waste properly.

This is made possible by the production of pipes sewer pipes which conveniently transport human waste.

A plastic extrusion machine manufactures this pipes.

2. Packaging tubes and paper bags

Another reason that you need a plastic extrusion machine is to manufacture packaging tubes and paper bags.

These products are useful in our daily lives since we use them to package a wide range of items.

By utilizing different manufacturing processes using a plastic extrusion machine, we can obtain these products.

3. Manufacture of water pipes

You need a plastic extrusion machine to manufacture plastic water pipes that helps in availing water in our homes.

Without a plastic extrusion machine, perhaps we could still be using the metal pipes which were rusty hence contamination of water.

One is also able to manufacture water storage tanks which we can use to store water for drinking. This is important for water harvesting during the rainy season.

4. Manufacture of drainage pipes

Drainage pipes are important during construction of a building. They can drain rainwater during the rainy season as well as in kitchen applications.

A plastic extrusion machine helps in manufacturing this pipes.

Advantages of a Plastic Extrusion Machine

Here are some of the benefits you achieve when you use a plastic extrusion machine:

- You will have a high output level of production.

- When you compare with other types of molding machines, a plastic extrusion machine is cheaper. This is regarding operations and the initial cost of purchasing the machine.

- A plastic extrusion machine is flexible thereby you can change the production of your product depending on your needs.

- A plastic extrusion machine allows for the thorough melting of the resins thereby you have uniform melt. Also, the availability of the screens ensures that you have a smooth melt.

- A plastic extrusion machine has a short lead time of production ensuring continuity in production.

Disadvantages of a plastic extrusion machine

Some of the limitations you will experience when you are using this machine are:

- Die swell results in size variance of the product. Since there are different causes of die swell, estimating the exact expansion degree is a challenge.

The result is that manufacturers have to do with significant levels of deviations.

- Plastic extrusion machine limits the type of products you can make. For instance, in the making of a soft drink bottle, you have to allow for an opening for the cap which most plastic extrusion machine can’t.

- Increase in pressure during extrusion may affect the quality of the product. This is because the polymer may not have melt completely by the time it exits the extruder.

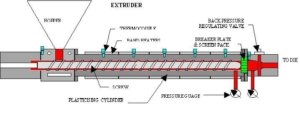

Figure 2 Screw extruder machine

Figure 2 Screw extruder machine

Parts of a Plastic Extrusion Machine

Since you will be using this machine often in production, you need to know the components that it constitutes.

The advantage is that you will be in a position to understand the source of the problem in case of malfunction.

Let’s understand these parts by looking at the types of extrusion machines available.

Single Screw Extruder

As a type of plastic extrusion machine, the single screw extruder is different from other types since it has only one screw.

For a single screw extruder, here are the parts that you will find.

Figure 3 Parts of a plastic extruder

· Vacuum Loader

A vacuum loader acts as a conveyor belt for your resins. What happens is that once you have placed the resins on the loader, conveying takes place to the hopper.

· Hopper

The hopper is the uppermost part of the plastic extrusion machine. You can identify this part due to its funnel shape.

The purpose is to hold the resins and allow them to flow into the extrusion machine. What happens is that you place the resins in the hopper and it flows gravitationally into the extrusion machine.

There are different sizes of hoppers which depend on the size of your plastic extrusion machine.

· Single screw and barrel

A barrel is an outermost part which is mostly cylindrical that is below the hopper and feed throat that houses the extruding screw. The barrel is also responsible for transmitting heat to the screw by conduction for melting of the resins.

Figure 4 Single screw extruder

It is along the barrel that the resins melt as they move from the feed throat at a different temperature.

There are different types of barrels available such as combo barrels, solid barrels, and vented barrels.

On the other hand, we have the single screw extruder.

As the name of the machine suggests, the single screw extruder uses one screw for the extrusion process.

You can find the extruding screw inside the barrel. The purpose of the screw is to help push the resins forward during the extrusion process. As it does this, the resins melt in a gradual but uniform manner.

The design of the screw is such that it can build pressure inside the barrel. This pressure ensures uniformity in the melting as well as provides forward push to the resins.

Generally, an extruding screw consists of the following zones: the feed zone, the melting zone, and a metering zone.

Each zone serves a specific purpose during the extrusion process as we shall later see.

· Gearbox- Guomao brand and Chang brand

The gearbox is another important component in the plastic extrusion process. You can locate this equipment normally on the sides of your plastic extrusion machine.

The gearbox conveys energy from the electric motor to the extruding screw which enables the screw to propel forward.

Another function of the gearbox is to regulate the speed of the electric motor to be in line with that of the extruding screw.

In case you are shopping for a quality brand of gearbox let me give you a hint. The guomao bran and chang brand tend to give a lasting performance, and they are cost effective.

· Electric motor- Siemens AC motor

For the plastic extrusion machine to work, there is a need for energy. The electric energy provides this energy by converting the electric energy from the mains to kinetic energy.

It is this kinetic energy that propels the plastic extrusion machine.

There are different sizes of electric motors which depend on the size of your plastic extrusion machine.

The difference is as a result of the different amount of energy the motor can supply to the plastic extrusion machine.

If you are looking for an electric motor that will give you service as well as save you cost, you can check out the Siemens AC motor.

· Heaters

Along the barrel, you will find a set of heaters. They are the ones that transmit heat to the barrel for conduction to take place.

It is this heat that melts the resins.

Heaters are a product of different materials such as aluminium and aluminium bronze alloy. As such, the range in temperature of different heaters will differ.

· Cooling system

After the production of your plastic product, the product must cool to maintain its shape. The cooling system serves this purpose.

There are two types of cooling system namely air and water cooling system. With air cooling system, the product passes through pressurized air to cool it.

This requires regulation since high pressurized air may result in warping of the product as a result of a sudden change in temperature.

Water cooling system is one that utilizes water to cool the plastic product. There are two ways you can cool your product using water.

You can use spray cooling where you spray your product with water to cool it. This is normally useful if the products are large.

The other type is immersion cooling. Using this method requires that you immerse your product in water to cool it.

Ideal if you are manufacturing products that are of small size thereby immersing in water becomes easy.

Whichever the method you utilize, you need to ensure that you have efficient water supply and that there is circulation.

· Extruder frame: 10mm thickness iron

The outer case of your extrusion machine needs to be strong enough to contain the activities that take place during the extrusion process. Preferably, it needs to be 10 mm thick and constitutes of iron.

· Temperature controller

For you to obtain a desirable plastic product, there is a need for the resins to melt evenly. The temperature controller helps you to achieve this by regulating the amount of heat inside the barrel.

Remember, for there to be uniform melting; there ought to be optimal temperature inside the barrel. In the market, the Omron brand of temperature controller has the edge over the other brands.

The reason is that it able to give accurate temperature controlling measurements and it is also cost-effective.

· Contactor

To regulate the operating currency of your plastic extrusion machine, you need a contactor. It helps in ensuring that there is no overload of the current on your machine allowing it to function properly

You can check out the Schneider brand of contactor if you want to make a purchase. Many extrusion industries use this brand due to its efficiency and cost-effectiveness.

· Schneider switch

To have control of the extrusion machine, you need to have a switch which turns on or off the machine. For effective working of your extrusion machine, you can check out the Schneider switch which performs efficiently.

· Driver: ABB inverter

In the plastic extrusion industry, electricity is the source of most of the energy. Perhaps one thing you need to know is that this energy is normally of low frequency.

As such you need an inverter to convert this energy from the low frequency to a higher frequency needed by the machines.

For efficiency in the conversion of the energy, the ABB inverter is the best brand in the market. Furthermore, it is cost effective.

Twin Screw Extruder

A twin screw extruder can be of two types.

· Conical Twin Screw Extruder

The conical twin screw extruder has a large surface area which it advantageous as it helps in the uniform transmission of heat.

Fig 5 Conical twin screw extruder

Another advantage of having a large surface area is that it increases the pumping efficiency of the melt into the die during extrusion.

· Parallel Twin Screw Extruder

The other type of a twin screw extruder is the parallel twin screw extruder. The parallel twin screw extruder is important when it comes to the blending, mixing and compounding of your melt.

Figure 6 Parallel twin screw extruder

The advantage you have when using this type of extruder is that it is easy to repair due to the availability of spare elements.

On the production side, the parallel twin screw extruder is had high torque and speed.

· Die

A die in the extrusion machine is where the formation of the plastic product takes place. Activities that you will find here include:

- Shaping the plastic product to the desired shape

- Regulation of the physical properties of the plastic product such as the smoothness

There are two types of die designs which depend on the breaking and distribution manner of the melt. They are the spider and basket die designs.

Since this is where plastic formation takes place, you can easily customize the die to suit the kind of plastic product you want.

· Vacuum pump

A vacuum pump exists to calibrate your plastic product and to further allow for slow cooling of your plastic product.

Technical Specifications of the Plastic Extrusion Machine

I hope you are progressing on well.

Let’s now deal with the technical specification of a plastic extrusion machine. This is regarding the performance specification of the plastic extrusion machine.

Have a look:

Performance Specification of the Plastic Extrusion Machine

When it comes to technical specifications, you must evaluate parameters that determine the normal operation of plastic extruder.

It is for this reason that you should review the technical datasheet before buying the machine.

You can have a quick look at this:

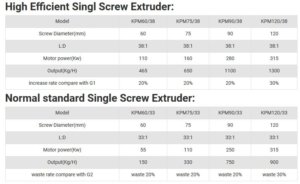

Figure 7 Single screw extruder technical data

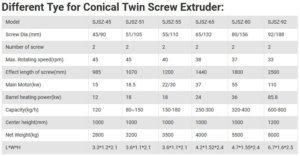

You can also compare this with the twin screw extruder technical data:

Figure 8 Technical data for twin screw extruder

Also, as you can see, the plastic extrusion machine designs vary depending on the type of machine.

I believe, you have seen this in the previous section – when comparing twin screw plastic extrusion machine and single screw plastic extrusion machine.

Working Principle of the Plastic Extrusion Machine

For a machine that will be operating in your company, you need to know how it works.

This will assist you in getting to know which part of the plastic extrusion machine handles a specific role in the extrusion process.

This section will help you understand the working principle of the plastic extrusion machine.

Keep reading.

Figure 9 Plastic extrusion process

To start off, the raw materials that you will need in the extrusion process are the resins or plastic pellets.

However, there are other ingredients such as colors that you can add depending on the type of plastic product you want to produce.

You will introduce the resins to the extruding machine by mounting them onto the hopper. From there, the resins flow to the barrel by gravity.

You can add colors and other ingredients at this point for mixing to take place.

From the hopper, the materials flow through the feed throat and get in touch with the rotating screw.

Since the screw is rotating, the materials are thrust forward into the barrel. As it does this, there is friction between the barrel walls, the screw, and the materials.

Due to the friction, there is the production of heat which starts melting the resins. Also, due to the friction, there is wear of the barrel and the extruding screw.

You need to continually check on the barrel and the screw to ensure that they are in good working condition.

Another source of heat at this stage is the barrel itself. Along the outer lining of the barrel, there are heaters which conduct heat to the barrel.

The barrel passes this heat to the resins melting it. The arrangement of the heaters is in such a way that heat increases as the resins move away from the feed throat.

The three sections of the screw are the feed zone, melting and the metering zone.

What happens in the feed zone is that the resins get in contact with the screw and the pushing forward starts. At this stage, melting of the resins takes place.

Then at the melting zone, complete melting of the resins takes place. Due to high temperature, there is a need to control overheating of the resins. For this to happen, there is a cooling system on the outer lining of the barrel.

Once the resins melt entirely, they exit the barrel at the other end passing through a series of screens. The screen consists of a breaker plate.

This screens remove any impurity that might be in the melt as well as particles which did not melt.

The breaker plate, on the other hand, helps in building the pressure in the barrel providing uniform melting and mixing of the melt.

After passing through the screens, the melt goes to the die. What happens in the die is that the melt takes its shape into a plastic product.

However, at times, there might be uneven flow of the molten plastic resulting in a poor plastic product.

This effect is known as die swell and can even result in plastic warping when the plastic product cools.

Once the formation of the plastic product is complete, it needs to cool down. The haul off unit pushes it through the cooling system for cooling to take place.

There are different methods of cooling your product here. You can use air cooling system where cold air is blown over the product to cool it.

You can also use a water cooling system where you can either immerse your product in water for the cooling to take place. You can also spray cold water on the product to cool it off.

Whichever the method you use, ensure that you control the system to avoid warping of the product.

After cooling, the plastic now moves to the vacuum pump where the product further cools. The essence of this stage is to allow the plastic to have its physical properties such as an appeal.

You can now move your product for storage using the bundling jig.

Applications of the Plastic Extrusion Machine

Now that we have dealt with the details of a plastic extrusion machine, it is important to know its applications.

Understanding the applications of a plastic extrusion machine will enable you to understand the different products it manufactures.

To help better understand these applications, let’s look at the forms of the different types of the extrusion machine

Single Screw Extruder

Some of the kinds of a single screw extruder include:

· HDPE solid pipe

One of the typical uses of a single screw extruder is in the manufacture of HDPE solid pipes. You might have come across one of these products in your households.

Figure 10 HDPE Pipes

Products such as drinking bottles, jugs, fuel tanks, plastic bags, plastic chairs, and plastic surgery come from HDPE solid pipes.

· PPR solid pipe

Another application of the single screw extruder is in the manufacture of PPR solid pipes. You can use these pipes in several areas. This include:

In residential and industrial projects, you can use these pipes in the plumbing section such as the piping of the water system.

Figure 11 PPR Pipes

You can also use them in air conditioning for piping compressed air. Even in the agricultural section, you can use in the piping water system.

The advantage you have with this pipes is that you can use them in piping either hot or cold substance.

· HDPE double wall corrugated pipe

HDPE double corrugated pipe wall has a wide area of applications. You can use it in the sewage system and the drainage system.

Figure 12 HDPE double wall corrugated pipe

The flexibility of these pipes allows for the use of these pipes in underground applications. Also, they are ideal due to the double walls which enables them to withstand pressure.

· HDPE single wall corrugated pipe

The difference between the HDPE single and double corrugated pipe is that the single wall corrugated pipe has one wall that is corrugated.

Figure 13 HDPE single wall corrugated pipes

The applications you have with these pipes are in the drainage system. You can conveniently use them on the golf course to maintain the drainage system of the park.

Also, you can use them on the playing field such as a football pitch.

Conical Twin Screw Extruder

You can use a conical twin screw extruder in the following applications.

· PVC solid pipe

You can find the application of conical twin screw extruder in the manufacturing of PVC solid pipes. These pipes have broad applications in our daily lives.

Figure 14 PVC Pipes

This includes in the drainage and vent systems. Generally, you can use them in cold water applications.

· PVC single wall corrugated pipe

PVC single wall corrugated pipes manufacturing is another area where you can find the application of a conical screw extruder. The use of these pipes includes in drainage and piping system.

Figure 15 PVC single wall corrugated pipes

You can find these pipes in a golf course or in the football pitch where they help in maintaining the cleanness of this pitch. They do this by draining excess water in the ground.

· PVC double wall corrugated pipe

These are other pipes that you can use in the drainage and piping system as a result of a conical twin screw extruder.

· Make window and door profiles

There is a variety of window and door profile that you can choose for your building which is a product of a conical twin screw. These profiles enable you to partition your structure carefully.

· Make ceiling profile

Another product of a conical twin screw is the ceiling profile. The application of these profiles is typical in building finishes.

The resulting product on the roof of a building is an attractive piece of the architect.

· Wall panel

Conical twin extruder produces a wall panel which you can use for on your wall. When you apply a wall panel on your walls, they act as a protective layer to your wall which in the long run reduces construction cost.

· PVC marble sheet/SPC flooring

PVC marble sheet/ SPC flooring is an alternative of natural stones when it comes to flooring your home. As a product of a conical twin screw extruder, they add a luster when you apply them, and they are also eco-friendly.

· PVC foam board extrusion machine

Another application of the conical twin screw extruder is in the PVC foam board extrusion machine. The function of this machine is to manufacture PVC foam boards which have broad applications.

You can use these boards in the manufacture of signs and displays which you can use for promotional advertisements. You can also use these boars in wall paneling and ceiling board.

The reason is that the physical properties have an attractive appeal.

· PVC roof tile extrusion line

Conical twin extruder also has an application in the PVC roof tile extrusion line. The machine manufactures PVC roof tiles which you can use in various forms.

For instance, you can use these tiles to roof your building. The advantage of these tiles is that they are lightweight, durable and rust resistant.

· PVC glazed roof tile extrusion line

Lastly, you can use a conical screw extruder in the PVC glazed roof tile extrusion line. This machine manufactures PVC glazed roof tiles.

You can use PVC glazed tiles in the roofing of your building and also in greenhouse roofing. The advantage of this roof is that they allow light to pass through.

Parallel Twin Screw Extruder

Lastly, when you are using a parallel twin extruder, you can apply it in the following areas.

· Plastic compounding

Plastic compounding refers to the process in which mixing of synthetic resins and additives take place to produce a variety of product. You can you a parallel twin screw extruder to compound resins with additives.

Such additives include wood chips, colours or stone marbles. The advantages of the twin screw being parallel to each other simplifies the compounding process.

Support Equipment for a Plastic Extrusion Machine

There is equipment which work in coordination with your plastic extrusion machine to produce your plastic product. You need to have an idea of what they are and their roles in the manufacturing process.

This section will help you to understand this.

Before we proceed, let’s look at some of the special support equipment that you need when producing a variety of extrusion products.

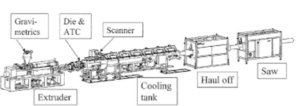

Figure 16 Plastic pipe extrusion

HDPE, PPR Pipe

The support equipment you will need for the production of an HDPE and PPR pipe include the following: Die, vacuum tank, cooling tank, haul-off, cutter, stocker or disc winder, Laser printer or a hand printer

PVC Pipe

In the manufacture of a PVC pipe, you will need a couple of equipment. They include Mixer, Die, vacuum tank, haul-off, cutter, stacker, socket machine, laser printer, ink-jet printer or hand printer.

PVC Profile Extrusion Line

PVC profile extrusion line has the following support equipment: Die, vacuum table, haul-off, cutter, stacker, and mixer

PVC Marble Sheet Extrusion Line

You will need the following support equipment when you are manufacturing PVC marble sheet extrusion line. T-DIE, three or four roller calendar, cooling bridge, haul off, cutter, stacker and a mixer.

PVC Roof Tile Extrusion Line

When you are manufacturing using a PVC roof tile extrusion line, you need to have the following support equipment. Die, forming die, haul-off, cutter, stacker and a mixer.

PVC Glazed Roof Tile Extrusion Line

If you want to manufacture a PVC glazed roof tile extrusion line, you will need the following support equipment. Die, forming machine, cutter, stacker and a mixer.

After identifying the support equipment, you will need to manufacture the various extrusion products, let’s define them.

Read along.

T-die

T shape die is the type of die has two arms which extend at right angles to the extrusion channel. There is a small slit in each of these arms that allow for flowing of the polymer melt.

Before pushing the melt along the die lips, it thins out.

Breaker Plate

The breaker plate refers to a solid steel state which is perforated. With the aid of screen packs, the breaker plate prevents foreign particles from entering the pipe wall.

The breaker plate also assists in building pressure gradient within the screw length. By doing so, it helps in having a uniform polymer.

Printer

You might need to print some information on the final plastic product after extrusion. That is the purpose of the printer. Printers come in different forms.

First is the laser printer which uses a laser to form images on the plastic product. What happens is that the laser beam passes back and forth on a drum which has a negative charge.

The drum then selects the ink forming an image which then prints it onto the plastic product.

The second form of a printer is the ink jet printer. The working of this type of printer is that there is propelling of ink droplets onto the plastic product resulting in the formation of an image.

There are two types of inkjet printers. That is the continuous inkjet printers and Drop on Demand ink jet printers.

Lastly, we have a handheld printer which you hold it in your hand when you are printing an image on the plastic product. The ease of this printer and its flexibility allows you to print an image on the synthetic product quickly and efficiently.

Bundling Jig

The function of the bundling jig is to hold the finished plastic products together during packaging. It helps in proper handling and arrangement of the plastic product.

Haul- off

The haul off refers to a unit that pulls the synthetic product forward as it moves during the extrusion process. It is vital in the extrusion process since it can push the product to the necessary stages.

It also determines the speed of the extrusion machine. There are different types and sizes of a haul off unit depending on the size of your extruding machine.

Peeling Tool

The purpose of the peeling tool is to form a uniform thickness of chip on the outside of the pipe. This is important in cases where you use the tubes for infusion purposes.

A common type of peeling tool is the rotational peeling tool.

Pipe Cutter

The purpose of a pipe cutter is to cut the pipes to ensure a perpendicular accurately, and uniform pipe ends. This ensures bulk production of the same length of pipes.

Pipe cutters commonly include a clamp and a saw or a knife.

Socket Machine

When it comes to making pipe joints on your plastic products, you will need a socket machine. There are two kinds of socket machines available that you can choose.

They include ring socket machine and plain socket machine.

Three or Four Roller Calendar

A roller calendar is important when it comes to the final touches of your of your plastic product. They are a series of rollers that assists in smoothening of the synthetic product giving it the perfect texture it requires.

You can have a set of four or three roller calendar for your extrusion machine.

Mandrel

A mandrel refers to a piece of equipment on which a synthetic product forms on by allowing the molten resin to rest upon it.

Mixer

The mixer aids in adequately mixing the raw materials to ensure uniformity during the extrusion process. By mixing the particles, the mixer ensures maximum de-airing of the particles in preparation for extrusion.

FAQs on the Plastic Extrusion Machine

By now there are questions you would like to get answers. However, I cannot answer them directly at the moment.

Figure 17 Plastic profile extrusion machine

But don’t worry.

You can have a look at some of the following frequently asked questions by our clients about a plastic extrusion machine.

1) What are the primary materials for plastic extrusion?

The primary materials include Polyethylene (PE), polycarbonate, polypropylene, polyvinyl chloride (PVC), acrylic, nylon (polyamides), polystyrene, acrylonitrile butadiene styrene (ABS) and acetyl.

2) Why is it necessary to dry some polymers before the extrusion process?

The reason for drying some polymers before the extrusion process is to prevent the degradation of the polymer. You see, there are some polymers which are hygroscopic meaning they absorb moisture from the surrounding.

During melting in such a state, the moisture degrades these materials to shorter polymer chains which results in poor performance. You, therefore, need to dry this polymer to eliminate moisture for optimal performance properly.

3) What is the L: D ratio?

The L: D ratio is the ratio of the flattened length against the screw diameter. This ratio is used to identify the extrusion machine and the extruding screw.

4) What is a screw compression ratio?

Screw compression ratio refers to the ratio of the feed channel to the metering channel depth.

5) Which mixing screws are available for my plastic extrusion machine?

There are different types of mixing screw that you can choose from for your plastic extrusion machine. However, the common ones include maddock mixer, pin mixer, spirex Z mixer, and a saxton mixer.

6) What is the cause of wear of the screw and barrel?

The primary cause of the wear of the barrel and the screw is friction. You see, as the screw pushes the resins, there is resistance between the barrel walls.

This causes friction which causes the barrel and screw to wear. As a result, you need to continually check and replace the screw and barrel in case of worn out.

Other causes of wear include: cold starting the screw, running the screw with no resins present and having wrong raw materials for extrusion.

7) What are the factors to consider when choosing an extruding screw?

There are several factors you need to consider when choosing a perfect extruding screw for you plastic extrusion machine. These factors include the type of polymer for processing, power usage, pressure development in the die and the output stability.

You can also factor in the melting limitation of the polymer as well as the type of mixing of the resins.

8) What is scaling up of the extruder?

Scaling up of the extruder refers to modifying the extruder from small production to large-scale production.

9) What are some of the limiting factors of the extruders that may affect scale- up?

Some of the limiting factors that will affect scaling up of the extruder include the motor power, production capacity, and downstream cooling capacity.

10) What is the importance of cooling the feed throat area?

The importance of cooling the feed throat area is to prohibit the raw materials from softening and being tacky and sticking in the feed throat. If this happens, it causes premature melt blockage in this area.

11) What is sharkskin and what are the causes of it?

Sharkskin refers to an irregular ridged distortion surface that is perpendicular to the direction of extrusion.

The sharkskin forms around the landing area in the die is as a result of rapid speeding of surface layers in the extrudate as it leaves the die.

12) Why do I have to cool the screw regularly?

Cooling the screw during extrusion is importance. Since the heating is continuous during the extrusion as well as feeding the resins into the feed throat, there is a need to cool the screw.

This action takes place in the feed zone of the screw. The reason is to prevent the resins to stick on the hot screw. It allows for the free movement of the resins forward during the extrusion process.

Still didn’t get an answer to your question? Don’t worry, you can get in touch with us, and we will be glad to clarify your issue.

13) What are some of the ways that can improve corrosion resistance in the barrel?

There are three ways of improving the corrosion resistance in the barrel. The first one is to use a bimetallic coating approach of the barrel which provides better wear resistance.

The second one is to nitride the inside of the barrel. However, this is not the best option when running abrasive fillers like glass or minerals.

The third approach is to have a barrel liner which is a thin-walled stainless steel glass that you insert in the barrel. You need to ensure that the liner fits correctly to minimize the presence of air gaps between the liner and the barrel.

Having air gaps causes a variation in the temperature of the barrel which may affect the melting rate of the resins.

Conclusion

So basically that is how a plastic extrusion machine works. It is not as complicated as it may appear implying that you can efficiently operate within a few days of learning.

You can also be in a position to detect and fix a problem when it occurs by merely following the working principles.

And what is more, there are arrays of plastic products you can manufacture using a plastic extrusion machine. This ensures that you have a ready market if you want into plastic product manufacturing.